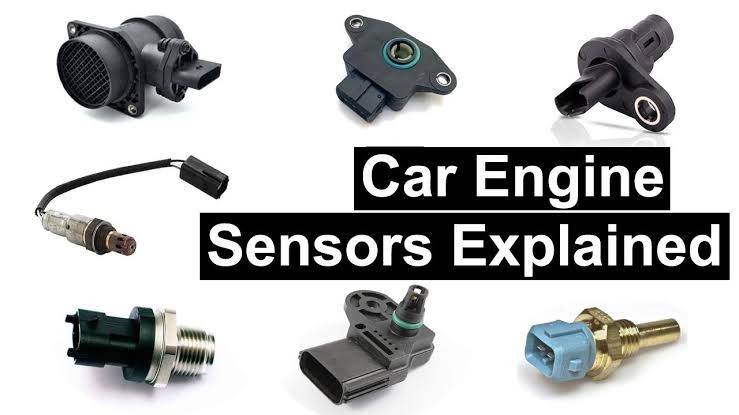

Engine sensors play a crucial role in optimizing car performance. From the Mass Airflow Sensor to the Throttle Pedal Position Sensor, understanding their functions and potential issues is essential for maintaining a smooth-running engine.

Your modern vehicle contains an astonishing 60 - 100+ sensors continuously monitoring everything from air pressure to fuel mixture. The automotive sensor market reached $39.5 billion in 2023 and is projected to grow at an 11.9% annual rate through 2030, highlighting the critical importance of these electronic components in today's vehicles.

After two decades working with engine diagnostics, I can tell you the difference between a $150 sensor replacement and a $2,000 engine rebuild often comes down to catching sensor failures early. Today's vehicles are marvels of electronic sophistication, but they rely entirely on accurate data from these critical components to make split-second adjustments thousands of times per minute.

Let me walk you through the 10 most crucial engine sensors every vehicle owner should understand, the ones that most frequently trigger problems and where a little knowledge delivers maximum return on your diagnostic dollar.

Oxygen (O2) Sensor

Arguably the most critical sensor in your vehicle's emissions system, the O2 sensor is also one of the most common sources of check engine lights nationwide.

- Function: Oxygen sensors measure the oxygen content in your exhaust gases, providing real-time feedback to your engine's computer to adjust the air-fuel mixture for optimal combustion efficiency.

- Location: Most vehicles have multiple O2 sensors positioned along the exhaust system, typically before and after the catalytic converter. A typical V6 or V8 engine may have 4 - 6 oxygen sensors.

Symptoms of failure:

- Decreased fuel economy (up to 40% in severe cases)

- Failed emissions tests

- Rough idling or hesitation during acceleration

- Illuminated check engine light

- Strong fuel smell from exhaust

- Maintenance tip: O2 sensors typically need replacement every 60,000 - 100,000 miles. Contrary to popular DIY advice, these sensors cannot be effectively cleaned, contaminated sensors must be replaced. Regular oil changes with the correct grade oil help prevent premature sensor failure by reducing contaminants in the exhaust.

- Replacement cost: $150 - $600 depending on the vehicle make, model, and sensor location. Upstream sensors (before the catalytic converter) are generally more expensive than downstream sensors.

Mass Airflow Sensor (MAF)

The MAF sensor is crucial for proper air-fuel mixture and engine performance, measuring incoming air volume and density with remarkable precision.

- Function: The MAF sensor measures the amount and density of air entering the engine, allowing the computer to calculate the precise fuel injection amount for optimal combustion.

- Location: In the air intake tract, between the air filter and the throttle body.

Symptoms of failure:

- Engine stalling shortly after starting

- Hesitation during acceleration

- Rough idling

- Excessive rich or lean running conditions

- Black smoke from exhaust

- Check engine light illumination

- Maintenance tip: MAF sensors can be cleaned with specialized MAF cleaner (never use general-purpose electronics cleaner!) every 25,000 - 30,000 miles. Always ensure your air filter is clean and properly installed to prevent contamination. A loose air filter can allow unfiltered air to damage the delicate sensor elements.

- Replacement cost: $150 - $400 including parts and labor.

Throttle Position Sensor (TPS)

This sensor translates your foot's pressure on the gas pedal into precise electronic signals the engine computer uses to adjust fuel delivery.

- Function: The TPS monitors the throttle valve position, providing data the engine computer uses to adjust fuel delivery and ignition timing.

- Location: Attached to the throttle body assembly.

Symptoms of failure:

- Sudden surges or drops in engine speed

- Poor acceleration

- Difficulty maintaining consistent speed

- Hard starting and stalling

- Erratic idle

- Unexpected shifts in automatic transmissions

- Maintenance tip: While the TPS itself rarely requires maintenance, keeping the throttle body clean helps prevent TPS issues. Consider a throttle body cleaning every 30,000 miles. Unlike some sensors, the TPS is sometimes housed within a sealed unit that cannot be cleaned effectively, failed units must be replaced.

- Replacement cost: $150 - $350 including parts and labor, depending on vehicle make and model.

Manifold Absolute Pressure (MAP) Sensor

The MAP sensor is critical for engines to adapt to changing atmospheric conditions and loads.

- Function: The MAP sensor monitors air pressure in the intake manifold to help determine engine load, allowing the computer to adjust ignition timing and fuel delivery for optimal performance and efficiency.

- Location: Mounted on or connected to the intake manifold.

Symptoms of failure:

- Engine misfires

- Poor fuel economy

- Hard starting

- Irregular idle

- Black smoke from exhaust

- Decreased power, especially at higher altitudes

- Maintenance tip: Check for vacuum leaks around the intake manifold and MAP sensor connection points periodically. These leaks are often the cause of MAP sensor problems rather than sensor failure itself. A smoke test can reveal hidden vacuum leaks.

- Replacement cost: $120 - $300 including parts and labor.

Crankshaft Position Sensor (CKP)

This critical sensor ensures your engine fires at precisely the right moment in the combustion cycle.

- Function: The CKP sensor monitors the position and rotational speed of the crankshaft, providing essential data for ignition timing and fuel injection synchronization.

- Location: Usually mounted near the main pulley at the front of the engine or on the side of the engine block.

Symptoms of failure:

- Engine refusing to start

- Stalling while driving (often without warning)

- Intermittent starting problems

- Check engine light illumination

- Random misfires

- Engine cutting out completely during operation

- Maintenance tip: There's no regular maintenance for the CKP sensor, but periodic inspection of its wiring harness can prevent failure due to chafed or damaged wires. This sensor often fails due to excessive heat exposure, so address any engine overheating promptly.

- Replacement cost: $150-$400 including parts and labor.

Camshaft Position Sensor (CMP)

Working alongside the crankshaft sensor, the camshaft position sensor ensures your valves open and close with perfect timing.

- Function: Working in conjunction with the crankshaft sensor, the CMP sensor monitors the position of the camshaft to ensure precise valve timing and fuel injection sequencing.

- Location: Usually mounted on the cylinder head or timing cover.

Symptoms of failure:

- Poor acceleration

- Engine misfires

- Difficulty starting

- Reduced fuel economy

- Stalling

- Check engine light illumination

- Maintenance tip: Maintain proper oil levels and quality, low oil or contaminated oil can damage both camshaft and crankshaft sensors. Oil sludge is a common cause of camshaft sensor failure. Stick to your manufacturer's recommended oil change intervals and oil specification.

- Replacement cost: $150 - $450 including parts and labor.

Engine Coolant Temperature (ECT) Sensor

This sensor helps your engine run efficiently from cold start to full operating temperature.

- Function: The ECT sensor monitors engine coolant temperature, allowing the computer to adjust fuel mixture and ignition timing based on engine temperature.

- Location: Typically threaded into the engine block or cylinder head, in contact with the coolant.

Symptoms of failure:

- Poor fuel economy

- Overheating

- Hard starting when cold

- Black smoke from exhaust

- Engine running too rich or lean

- Temperature gauge giving incorrect readings

- Cooling fans not activating properly

- Maintenance tip: Regular coolant flushes (every 30,000 - 50,000 miles) prevent corrosion and deposit buildup that can damage the ECT sensor. Never use tap water in your cooling system, always use proper antifreeze/coolant mixtures according to manufacturer specifications.

- Replacement cost: $150 - $250 including parts and labor. While the sensor itself is often inexpensive ($20 - $80), labor costs can increase if the sensor is in a difficult-to-reach location.

Knock Sensor

Your knock sensor is essentially a sophisticated microphone listening for the potentially destructive sounds of engine knock.

- Function: This sensor detects engine knock or detonation, allowing the computer to retard ignition timing to prevent engine damage.

- Location: Mounted on the engine block or cylinder head.

Symptoms of failure:

- Engine pinging or knocking

- Reduced power

- Poor acceleration

- Decreased fuel economy

- Illuminated check engine light

- Engine damage if left unaddressed

- Maintenance tip: Always use the recommended octane fuel for your vehicle. Lower-grade fuel increases the likelihood of engine knock, which causes the knock sensor to adjust timing constantly, potentially shortening its lifespan. Carbon deposits can also trigger false knock detection, so consider fuel system cleaners periodically.

- Replacement cost: $200 - $500 including parts and labor, with luxury and performance vehicles trending toward the higher end.

Fuel Pressure Sensor

Modern fuel injection systems rely on precise pressure readings to deliver exactly the right amount of fuel for every driving condition.

- Function: This sensor monitors the pressure in the fuel rail, helping maintain optimal fuel delivery to the injectors under varying engine loads and speeds.

- Location: Mounted on the fuel rail or connected via a fuel line.

Symptoms of failure:

- Hard starting

- Engine hesitation during acceleration

- Stalling

- Poor fuel economy

- Check engine light illumination

- Vehicle entering "limp home" mode

- Strong fuel odor

- Maintenance tip: Replace your fuel filter according to manufacturer recommendations (typically every 30,000 - 50,000 miles) to prevent contaminants from damaging the fuel pressure sensor. Using quality fuel from reputable stations helps reduce contamination that can clog filters and damage sensors.

- Replacement cost: $200 - $450 including parts and labor, with luxury and European vehicles typically costing more.

Exhaust Gas Recirculation (EGR) Valve Position Sensor

This emissions-focused sensor helps your vehicle meet stringent environmental regulations while maintaining optimal performance.

- Function: The EGR position sensor monitors the EGR valve, which recirculates a portion of exhaust gases back into the combustion chamber to reduce harmful NOx emissions and improve efficiency.

- Location: Mounted on or integrated with the EGR valve, typically on the intake manifold.

Symptoms of failure:

- Engine pinging

- Rough idle

- Failed emissions test

- Reduced fuel economy

- Stalling at low speeds

- Check engine light illumination

- Maintenance tip: Carbon buildup is the primary cause of EGR system failures. Consider an EGR system cleaning every 60,000 miles to prevent sensor and valve issues. In diesel engines, using quality fuel and proper additive packages can significantly extend EGR system life by reducing carbon deposits.

- Replacement cost: $250 - $450 for the EGR valve and sensor assembly, including labor.

Putting Your Knowledge to Work

Understanding these ten critical engine sensors won't transform you into a master mechanic overnight, but it will arm you with the knowledge to have more productive conversations with your mechanic and potentially save thousands in unnecessary repairs.

When that check engine light illuminates (and statistics show it eventually will), don't panic! Have the code read (many auto parts stores offer this service for free), and use the information in this article to get a basic understanding of what you're dealing with. Sometimes, the solution might be as simple as tightening a gas cap or cleaning a sensor.

Modern engines are incredibly resilient but rely entirely on precise information from these sensors. Addressing sensor issues promptly not only prevents larger problems but can significantly improve fuel economy and extend engine life. The average vehicle now contains between 60 - 100 sensors, with luxury and newer models exceeding 200 in some cases. With that many electronic components, understanding the most critical ones gives you a significant advantage in maintenance and troubleshooting.

Remember, the sensors don't cause problems; they report them. When a sensor indicates an issue, ignoring it doesn't make the problem disappear. Instead, it removes your engine's ability to compensate, potentially turning a small issue into an expensive repair.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion