The $15 billion global automotive EGR market tells a story that every car owner needs to hear.

These tiny valves, often no bigger than your fist, are responsible for keeping millions of vehicles compliant with emissions standards while quietly working in one of the harshest environments imaginable. Yet when they fail, they can turn your reliable daily driver into a stuttering, fuel-guzzling nightmare faster than you can say “check engine light.”

I've spent over two decades diagnosing EGR problems, and I can tell you this: understanding your EGR system isn't automotive rocket science. It's about knowing when to act before a $150 cleaning becomes a $1,000 replacement nightmare.

What Your EGR System Actually Does

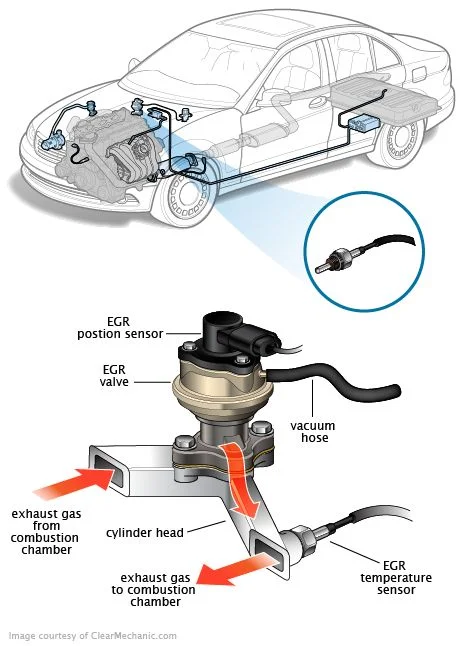

Your Exhaust Gas Recirculation system works on a brilliantly simple principle. Nearly 80% of the air we breathe is nitrogen, which remains inert under normal conditions. However, when exposed to combustion temperatures exceeding 1,370°C (2,500°F), this harmless gas transforms into harmful nitrogen oxides (NOx) that contribute to smog formation.

The EGR valve's job is elegant in its simplicity. It recirculates a precisely controlled amount of exhaust gas back into the intake manifold, effectively diluting the fresh air-fuel mixture. This reduces combustion temperatures by up to 150°C, dramatically cutting NOx production by as much as 50% in some applications.

Think of it as your engine's environmental conscience. When you're cruising at highway speeds with minimal load, the EGR valve can open up to 90%, significantly reducing emissions. But when you floor the accelerator demanding maximum power, the valve snaps shut, ensuring every molecule of oxygen reaches the combustion chamber for optimal performance.

"My truck runs fine, why should I care about some emissions valve?" I hear this constantly from customers. Here's why you should care: a properly functioning EGR system doesn't compromise performance when working correctly. In fact, in modern gasoline direct injection engines, EGR actually improves fuel efficiency by reducing pumping losses and enhancing knock tolerance.

Recognizing the Warning Signs

EGR valve failure rarely happens overnight. The symptoms build gradually, and recognizing them early can save you hundreds of dollars and prevent potentially catastrophic engine damage.

The Telltale Check Engine Light

Your powertrain control module continuously monitors EGR performance through various sensors. When the system detects irregularities, it illuminates the check engine light and stores diagnostic trouble codes like P0401 (insufficient flow) or P0402 (excessive flow). Don't ignore this warning, it's your first and cheapest opportunity to address the problem.

Engine Performance Issues That Scream EGR Problems

A failing EGR valve creates a domino effect of performance problems. You might notice rough idling that makes your morning coffee vibrate in the cup holder. Cold starts become increasingly difficult, requiring multiple attempts to fire up the engine. Acceleration feels sluggish, as if you're towing an invisible trailer.

"But it still gets me to work!" Sure, but at what cost? A stuck-open EGR valve can reduce fuel economy by 10-15% while a stuck-closed valve creates combustion temperatures hot enough to cause serious internal engine damage.

The Dreaded Engine Knock

When your EGR valve sticks closed, combustion temperatures skyrocket. This leads to spark knock, that metallic pinging sound under acceleration that makes experienced mechanics wince. Ignore this symptom, and you're looking at potential piston damage, blown head gaskets, or worse. I've seen engines destroyed because owners thought the knocking would “work itself out.”

The Real Causes Behind EGR Failure

Understanding why EGR valves fail helps you prevent future problems and make informed repair decisions.

Carbon Buildup: The Silent Killer

The single biggest enemy of EGR valves is carbon accumulation. Exhaust gases contain microscopic soot particles that gradually coat the valve mechanism, EGR passages, and intake manifold. Over time, this carbon cement hardens, preventing the valve from opening or closing properly.

Diesel engines face particular challenges here. High-pressure EGR systems route sooty exhaust gases directly back into the intake before filtration. This soot combines with oil vapor to create a tar-like sludge that can completely block passages in as little as 30,000 miles under severe operating conditions.

Operating Environment Extremes

EGR valves endure conditions that would destroy most mechanical components. They experience temperature swings from sub-zero cold starts to scorching exhaust heat exceeding 800°C. The valve mechanism must function flawlessly while bathed in corrosive exhaust gases containing sulfur compounds, water vapor, and acidic condensation.

"I maintain my vehicle religiously, why did my EGR valve still fail?" Even with perfect maintenance, EGR valves are wear items with finite lifespans. Most quality valves last 80,000-120,000 miles, but operating conditions greatly influence longevity.

Professional Troubleshooting

Proper EGR diagnosis requires systematic methodology, not guesswork. I've seen too many unnecessary valve replacements because technicians skipped fundamental diagnostic steps.

Step 1: Read the Codes (But Don't Stop There)

Modern scan tools provide invaluable diagnostic information, but codes only point toward the problem area. A P0401 code indicating "insufficient EGR flow" could result from a stuck valve, blocked passages, faulty position sensor, or vacuum supply issues.

Professional-grade scan tools allow active testing of electronically controlled EGR valves. You can command the valve open while monitoring position feedback and intake manifold vacuum changes. This real-time data reveals whether the valve responds to commands and achieves proper flow rates.

Step 2: Visual and Physical Inspection

Remove the EGR valve for thorough inspection. Look for obvious carbon buildup on the valve seat and pintle mechanism. Check vacuum lines for cracks, kinks, or deterioration. Inspect electrical connections for corrosion or damage.

"Can't I clean the carbon off myself?" Absolutely, but use caution. Carburetor cleaner effectively dissolves carbon deposits, but avoid getting cleaning solution on rubber diaphragms or electrical components. Ultrasonic cleaning provides superior results for heavily contaminated valves.

Step 3: Test System Function

Apply vacuum directly to the EGR valve using a hand pump while monitoring engine idle quality. A properly functioning valve should cause noticeable idle roughness when opened at idle speed. No change indicates either valve malfunction or completely blocked passages.

For electronically controlled valves, use scan tool bidirectional controls to cycle the valve while observing position sensor feedback. Discrepancies between commanded and actual position indicate mechanical binding or sensor problems.

Repair Solutions That Save Money Long-Term

When Cleaning Makes Sense

Professional EGR valve cleaning costs $150-$400 and often restores full functionality to carbon-fouled valves. The process involves complete disassembly, ultrasonic cleaning of metal components, and replacement of rubber seals and gaskets.

Cleaning works best when carbon accumulation is the primary problem without mechanical wear or damage. Valves with scores, warped seats, or torn diaphragms require replacement regardless of cleaning efforts.

Replacement: Doing It Right the First Time

EGR valve replacement costs vary dramatically by vehicle type and valve complexity. Simple vacuum-operated valves might cost $150-$300 including labor, while sophisticated electronic units can exceed $800.

"Should I buy the cheapest replacement valve available?" I strongly recommend OEM or equivalent quality parts. Cheap aftermarket valves often fail within 12-24 months, while quality units last 100,000+ miles. The labor cost is identical whether you install a $50 or $250 valve, so invest in longevity.

Essential Post-Installation Procedures

Modern vehicles often require EGR valve adaptation procedures after replacement. This allows the powertrain control module to learn the valve's precise open and closed positions for optimal control. Skipping this step can cause immediate failure or poor performance.

Always clear diagnostic codes and road test the vehicle thoroughly. Verify that the malfunction indicator lamp remains extinguished and engine performance returns to normal across all operating conditions.

Prevention Strategies

Quality Fuel and Oil Choices

Use Top Tier certified fuels containing enhanced detergent packages that help minimize carbon formation throughout the intake system. Change engine oil at manufacturer-specified intervals using the correct viscosity grade. Degraded oil contributes to sludge formation that can compromise EGR operation.

Operating Habits That Extend EGR Life

Avoid excessive idle time whenever possible. Extended idling promotes carbon buildup while preventing the high exhaust temperatures needed to keep EGR passages clean. Take your vehicle on regular highway drives that allow the engine to reach full operating temperature and burn off accumulated deposits.

“I heard I can delete the EGR system entirely, is that smart?” Removing emissions equipment is federally illegal for street driven vehicles and can result in substantial fines. More importantly, EGR deletion often causes other problems including increased engine knock and reduced fuel economy.

EGR systems represent critical emissions control technology that, when properly maintained, provides years of trouble-free operation. Recognizing symptoms early, performing proper diagnosis, and investing in quality repairs prevents minor issues from becoming major expenses.

The next time your check engine light illuminates or you notice performance changes, remember that early intervention with EGR problems typically costs hundreds, not thousands. Your wallet and the environment will thank you for taking action before that small valve becomes a big problem.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion