Auto repair costs jumped 25% between 2022 and 2024, with fuel system problems ranking among the most common issues bringing vehicles into repair shops. Yet most drivers ignore the symptoms until their wallet takes a serious hit.

"My car starts fine, so the injectors must be okay." That's what drivers tell me right before spending $2,000 on repairs that could have been prevented with a $150 cleaning service.

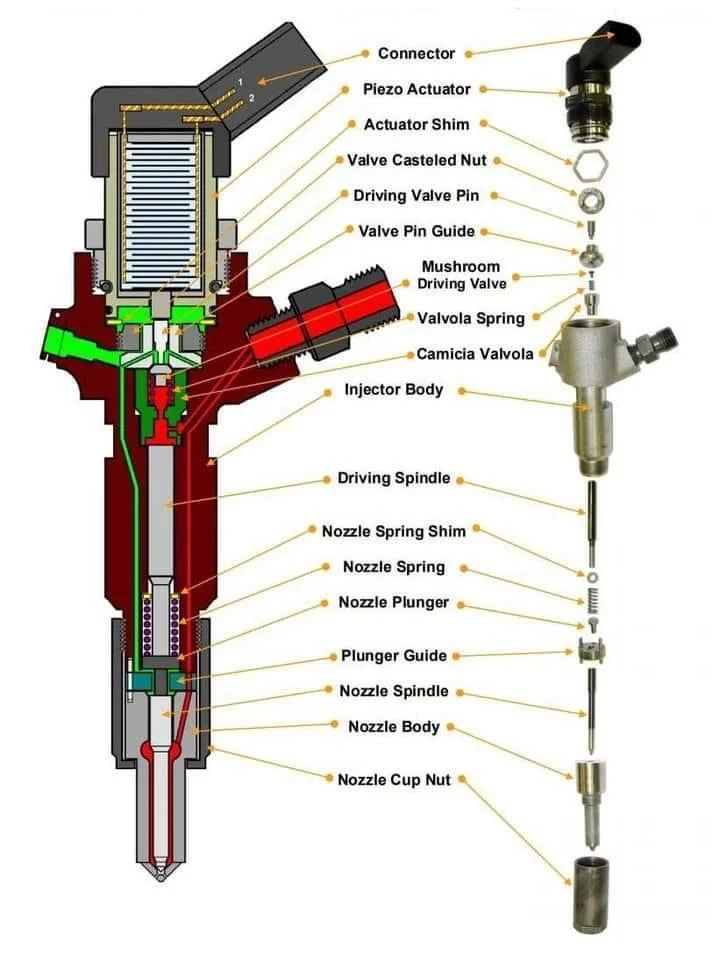

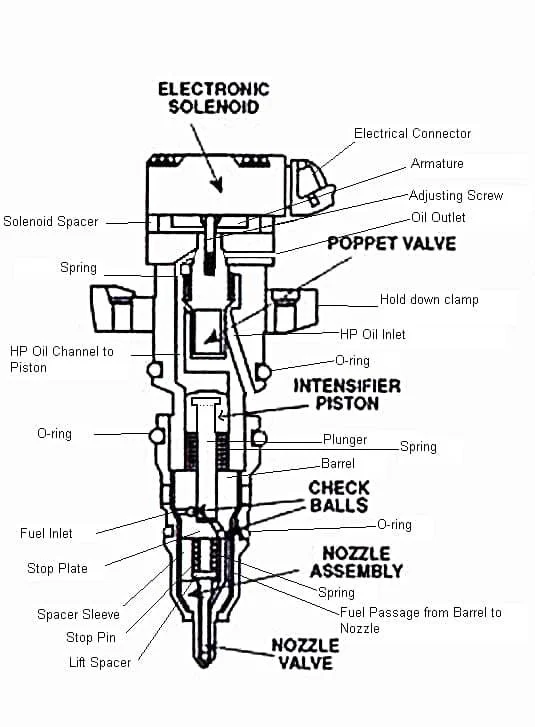

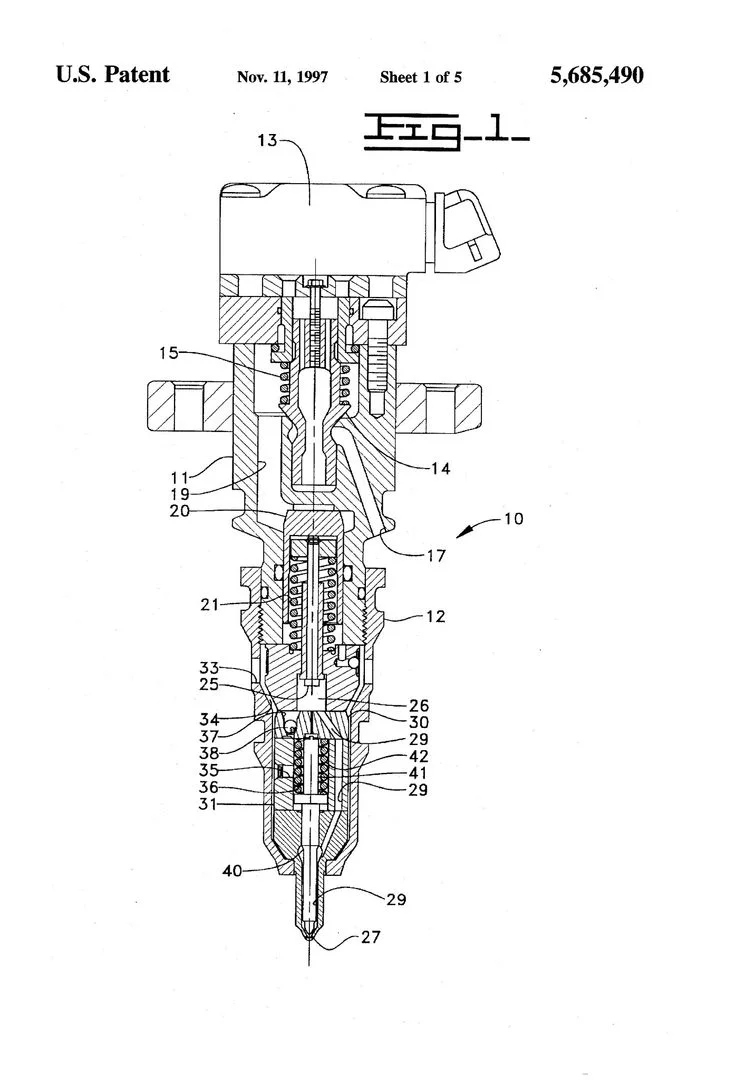

Understanding Injector Nozzle Components

The Nozzle Assembly

The injector nozzle sits at the heart of your fuel delivery system. This precision engineered component contains microscopic passages that atomize fuel into a fine mist. The nozzle needle, actuated by electromagnetic or piezo systems, opens and closes thousands of times per minute.

Modern injectors operate under extreme pressures. Port fuel injectors work at 30 - 80 PSI, while direct injection systems push fuel at 2,000+ PSI. These pressures demand tolerances measured in microns.

Critical Internal Parts

The solenoid coil creates the magnetic field that lifts the pintle valve. When energized, it allows pressurized fuel to flow through calibrated orifices in the nozzle tip. The spring mechanism ensures precise closure when the electrical signal stops.

O-rings and seals prevent fuel leakage while maintaining system pressure. These rubber components deteriorate over time, especially when exposed to ethanol-blended fuels that act as solvents.

Recognizing Injector Problems Early

Performance Symptoms

Rough idle ranks as the first sign of injector trouble. One clogged injector creates an imbalance that shakes the entire engine. You'll feel it most at red lights when the engine struggles to maintain steady RPMs.

Poor acceleration follows rough idle. "It used to have more power," drivers explain when describing sluggish throttle response. Dirty injectors can't deliver adequate fuel during high-demand situations like highway merging.

Fuel Economy Changes

Clogged injectors force your engine to work harder, consuming more fuel to produce the same power. A 15 - 20% drop in fuel economy often indicates multiple injectors need attention.

Black exhaust smoke signals overly rich combustion from leaking injectors. These injectors dump excess fuel that can't burn completely, creating visible emissions and potential catalytic converter damage.

Engine Codes and Misfires

Check engine lights with P030X codes indicate cylinder-specific misfires. These diagnostic trouble codes pinpoint which injector needs attention, saving valuable diagnostic time.

Troubleshooting Techniques That Work

Visual Inspection Methods

Remove the engine cover and inspect injector bodies for external fuel leaks. Wet spots around injector seals indicate O-ring failure. Clean the area thoroughly and run the engine to verify active leaks.

Check fuel rails for pressure bleeding. Schrader valves allow pressure testing with specialized gauges. Low pressure readings indicate pump problems, while fluctuating pressure suggests injector leakage.

Electronic Testing

Measure injector resistance with a digital multimeter. Most injectors read 12 - 16 ohms, though specifications vary by manufacturer. Readings outside this range indicate internal coil damage.

Noid lights test injector pulse signals from the engine control module. Connect the light to the injector harness and crank the engine. No flashing indicates electrical problems in the control circuit.

Flow Testing Procedures

Professional shops use ultrasonic cleaning tanks combined with flow benches to restore injector performance. This process removes carbon deposits while verifying spray patterns and flow rates.

Each injector should flow within 5% of specifications when tested at operating pressure. Greater variations create cylinder-to-cylinder imbalances that affect drivability and emissions.

Repair Solutions and Costs

Chemical Cleaning Options

In-tank fuel system cleaners cost $8 - 15 and provide basic maintenance for lightly contaminated injectors. Products containing polyisobutylamine (PIBA) dissolve fuel deposits effectively when used regularly.

Professional fuel system cleaning services run $150 - 250 and include pressurized cleaning through the fuel rail. This method reaches areas that in-tank additives cannot access.

Ultrasonic Restoration

Off car ultrasonic cleaning provides the most thorough restoration. Services charge $150 - 400 for complete injector reconditioning, including new seals and flow testing. This process removes stubborn carbon deposits that resist chemical cleaning.

Replacement becomes necessary when internal components fail. Individual injectors cost $100 - 300 each, while complete sets range from $400 - 1,200 depending on engine type.

Professional vs DIY Approaches

"I can clean them myself with some carburetor cleaner." This approach rarely works and often damages delicate internal components. Professional equipment applies precise pressures and temperatures that home methods cannot replicate.

Ultrasonic cleaners designed for injectors cost $2,000 - 5,000, making professional service more economical for occasional maintenance.

Prevention Strategies

Fuel Quality Matters

Top tier gasoline contains detergent packages that prevent injector fouling. Brands meeting EPA standards cost slightly more but reduce long-term maintenance expenses significantly.

Water contamination accelerates injector corrosion. Replace fuel filters every 30,000 miles and address tank condensation issues promptly to prevent internal damage.

Maintenance Scheduling

Service intervals depend on driving conditions and fuel quality. City driving with frequent stops creates more deposits than highway cruising at steady speeds.

Clean injectors every 30,000 - 50,000 miles for optimal performance. This preventive approach costs less than reactive repairs after problems develop.

Fuel injector problems don't fix themselves. They worsen progressively until complete failure occurs, often at the most inconvenient times. Early intervention through proper diagnosis and cleaning prevents costly repairs.

"I'll wait until they completely fail before doing anything." This strategy guarantees maximum repair costs and potential collateral damage to other engine components.

Professional injector service costs $150 - 400 per visit. Compare that to $1,200+ for complete injector replacement, and the value becomes clear. Your engine's fuel system deserves the same attention you give your oil changes.

Smart drivers maintain their injectors before problems develop. The few hundred dollars spent on preventive service saves thousands in emergency repairs later.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion