87% percent of brake noise complaints occur within the first 500 miles of new pad installation. This statistic reveals a frustrating reality that countless drivers face every day.

You've invested in quality brake pads, paid for professional installation, and expected whisper quiet stopping power. Instead, your morning commute sounds like a dying banshee every time you touch the pedal.

"These brakes are brand new, they shouldn't make any noise!" I hear this complaint weekly in my shop. The truth is, new brakes can squeal for several legitimate reasons that have nothing to do with defective parts or poor workmanship.

The Physics Behind Brake Squeal

Brake squeal occurs when your brake system creates vibrations that resonate at specific frequencies. Think of it like a violin bow across strings. When brake pads contact rotors, they can generate high frequency oscillations between 1,000 and 16,000 Hz. These vibrations amplify through your brake components, creating that unmistakable screech.

New brake pads are particularly susceptible to this phenomenon. The fresh friction material hasn't yet conformed to your rotor's surface, creating uneven contact patches that vibrate during braking.

Material Composition Matters

Modern brake pads use three primary material types, each with distinct noise characteristics:

- Ceramic pads: Composed of ceramic fibers, non-ferrous fillers, and high-temperature resins. These pads generate noise through their dense material structure, which can create resonant vibrations when contacting rotors.

- Semi metallic pads: Containing 30 - 65% metallic elements including iron, steel, and copper. The metal particles in these pads can create grinding or squealing sounds, especially during the break-in period.

- Organic pads: Made from phenolic resins and various organic fibers. While typically quieter, they can still produce noise if contaminated or improperly installed.

The Break In Period Reality

Every new brake pad requires a bedding in process. During the first 200 - 300 miles, your pads transfer a thin layer of friction material onto the rotor surface. This process creates proper contact between pad and rotor while establishing optimal friction characteristics.

During break in, noise is common and often temporary. The pads are literally reshaping themselves to match your rotor's surface. Uneven contact during this period frequently causes squealing that disappears once bedding is complete.

Installation Variables That Create Noise

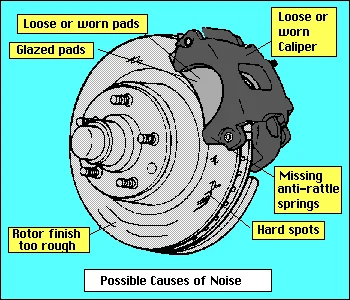

Even perfect brake pads can squeal due to installation factors:

- Missing anti squeal Shims: These thin metal or rubber pieces dampen vibrations between the pad and caliper. Mechanics sometimes omit these during installation, leading to immediate noise issues.

- Improper lubrication: Brake components require specific lubricants applied to precise locations. Missing or incorrect lubrication allows metal-to-metal contact that generates squealing.

- Rotor surface condition: New pads installed on grooved, glazed, or contaminated rotors will squeal. The uneven surface prevents proper pad-to-rotor contact, creating vibrations.

- Caliper problems: Sticking calipers cause uneven pad wear and pressure distribution, leading to noise and premature failure.

Environmental Factors

Weather conditions significantly impact brake noise:

- Morning moisture: Overnight humidity creates a thin water layer on rotors. The first few brake applications often squeal until this moisture evaporates.

- Temperature variations: Cold temperatures make brake materials harder and more prone to vibration. Many drivers notice increased squealing during winter months.

- Road contamination: Salt, sand, and debris embedded in brake pads create noise by altering surface friction characteristics.

Quality Control Issues

Not all new brake pads are created equal. Manufacturing defects that cause squealing include:

- Inconsistent material density: Variations in pad composition create uneven friction surfaces that vibrate during braking.

- Embedded contaminants: Foreign particles trapped during manufacturing can cause noise and accelerated wear.

- Improper curing: Brake pad resins require precise temperature curing. Undercured or overcured pads develop glazing that causes squealing.

When to Worry About Brake Noise

Most new brake squeal is harmless, but certain sounds require immediate attention:

- Grinding noises: Metal to metal contact indicates worn pads or damaged rotors. This requires immediate repair to prevent safety hazards.

- Pulsating squeals: Rhythmic noise often indicates warped rotors or uneven pad wear patterns.

- Squealing during non braking: Constant noise while driving suggests stuck calipers or severely worn components.

Practical Solutions for New Brake Squeal

If your new brakes are squealing, try these approaches:

- Drive normally: Allow 200 - 300 miles for proper break-in. Avoid aggressive braking during this period unless necessary for safety.

- Check installation: Ensure all anti-squeal shims are properly installed and brake hardware is correctly lubricated.

- Rotor inspection: Verify that rotors are clean, smooth, and free from contamination or damage.

- Professional evaluation: If squealing persists beyond the break-in period, have your brake system professionally inspected.

The Cost of Ignoring Brake Noise

While new brake squeal is often cosmetic, ignoring persistent noise can lead to expensive consequences. Continued vibration accelerates pad and rotor wear, potentially requiring premature replacement that costs $300 - 800 per axle.

"My brakes work fine, the noise doesn't bother me," some customers say. Unfortunately, brake noise often indicates underlying issues that worsen over time, leading to safety hazards and increased repair costs.

Prevention Strategies

Minimizing new brake squeal starts with proper selection and installation:

- Choose quality parts: Premium brake pads from reputable manufacturers typically include better noise dampening features.

- Professional installation: Experienced technicians understand the importance of proper lubrication, hardware replacement, and break-in procedures.

- Rotor maintenance: Resurface or replace rotors when installing new pads to ensure optimal surface contact.

New brake squeal is frustrating but usually temporary. Understanding the causes helps you distinguish between normal break-in noise and genuine problems requiring attention. Most importantly, never ignore persistent or unusual brake sounds. Your safety depends on properly functioning brakes, and professional diagnosis ensures any issues are addressed before they become dangerous.

Remember, squealing new brakes are often just finding their voice. Give them time to settle in, but keep your ears open for sounds that don't belong.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion