Every second, your car's engine makes thousands of precise calculations that would make a NASA engineer proud.

Behind this computational marvel sits a device smaller than a paperback book that processes more data than early computers used to send humans to the moon. The Engine Control Unit (ECU) has revolutionized how we think about automotive performance, transforming mechanical systems into sophisticated digital networks that adapt in real-time to your driving demands.

Modern vehicles can house up to 150 ECUs working all together! Each one serves as a dedicated computer managing specific vehicle systems. Yet despite their critical importance, most drivers remain unaware of how these electronic brains orchestrate everything from fuel delivery to emissions control. Understanding ECU functionality isn't reserved for engineers anymore. Today's mechanics, technicians, and automotive enthusiasts need this knowledge to diagnose problems, optimize performance, and maintain increasingly complex vehicles.

The ECU's Core Mission

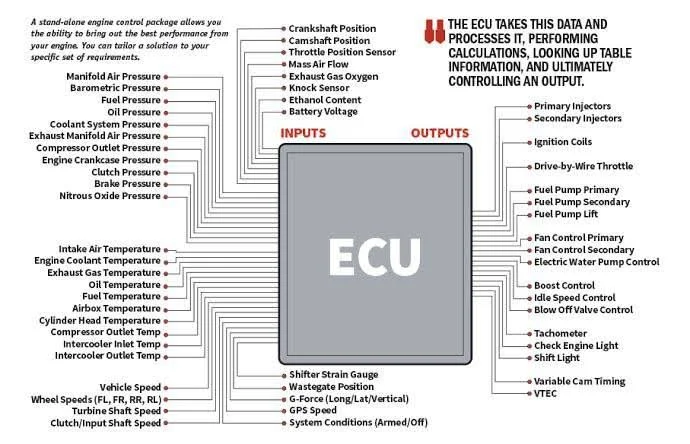

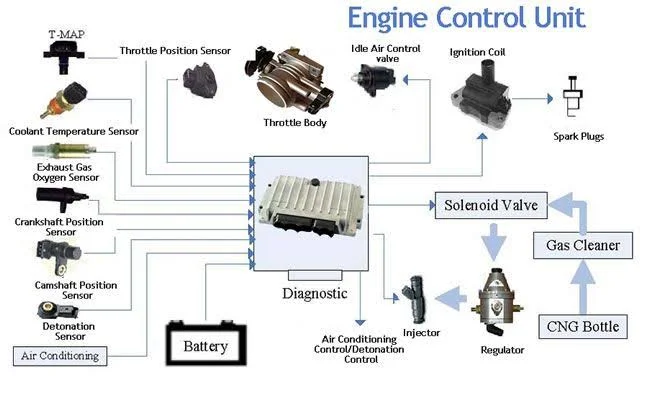

Think of your ECU as an orchestra conductor managing dozens of instruments simultaneously. It receives input from sensors scattered throughout your vehicle, processes this information using sophisticated algorithms, then sends precise commands to actuators that control engine functions. This happens thousands of times per second while you're driving.

The primary ECU handles engine management with laser-like focus on three critical areas: fuel delivery, ignition timing, and emissions control. Each decision affects the others, creating a delicate balance that determines whether your engine runs smoothly or struggles with performance issues.

Modern ECUs utilize microcontroller units (MCUs) as their computational core. These processors execute real-time operations, ensuring your engine responds instantly to changing conditions. When you press the accelerator, the ECU doesn't simply increase fuel flow. It calculates the optimal air-fuel mixture based on throttle position, engine temperature, altitude, and dozens of other variables before making adjustments.

The ECU's Information Network

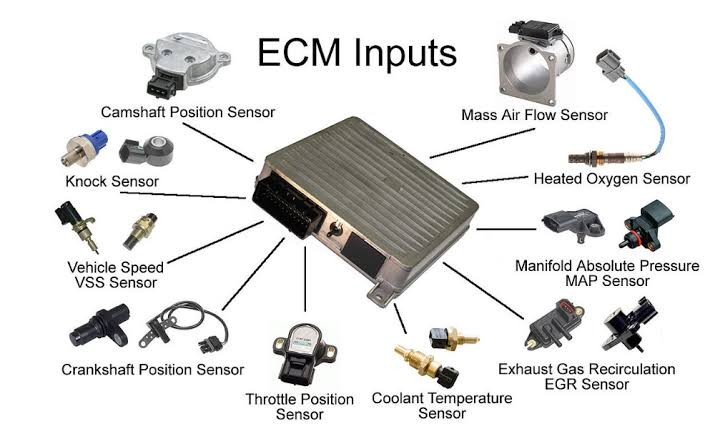

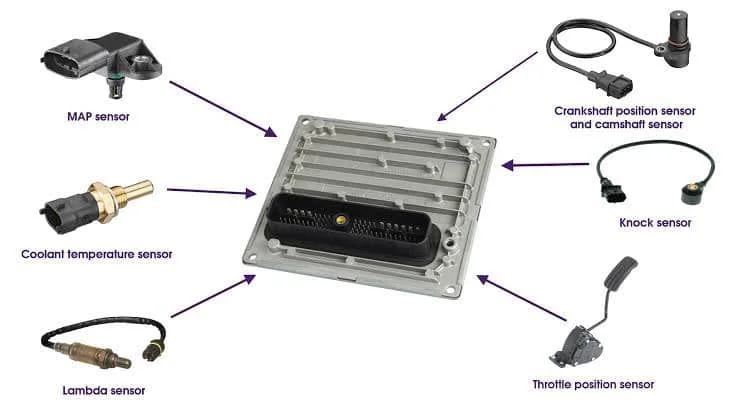

Your ECU relies on a sophisticated sensor network to make informed decisions. Let me break down the most critical input sensors that feed data to your engine's electronic brain.

- Oxygen Sensors (O2 Sensors) monitor exhaust gases to determine combustion efficiency. Located in your exhaust system, these sensors detect oxygen levels in spent gases, helping the ECU maintain the ideal air-fuel ratio. When your O2 sensor reports rich or lean conditions, the ECU adjusts fuel injection accordingly. A failing oxygen sensor can trigger poor fuel economy and increased emissions.

- Crankshaft Position Sensors track your engine's rotational speed and position. This information is absolutely critical! Without it, your ECU cannot determine when to fire fuel injectors or trigger ignition coils. The sensor monitors magnetic pulses from a toothed wheel attached to your crankshaft, providing precise timing data for engine synchronization.

- Throttle Position Sensors (TPS) tell your ECU exactly how much you're pressing the accelerator pedal. Modern electronic throttle systems have replaced mechanical linkages with drive-by-wire technology. The TPS sends voltage signals between 0-5 volts to indicate throttle position, enabling smooth acceleration and optimal fuel efficiency.

- Manifold Absolute Pressure (MAP) Sensors measure vacuum and pressure inside your intake manifold. This data helps the ECU calculate engine load and determine appropriate fuel delivery. During acceleration, manifold pressure increases, signaling the need for more fuel. At idle, high vacuum levels indicate minimal load conditions.

- Mass Airflow (MAF) Sensors measure the actual volume of air entering your engine. Rather than estimating airflow, MAF sensors provide direct measurements that enable precise fuel calculations. Clean airflow measurement is essential for optimal performance and emissions compliance.

Essential Output Actuators

Once your ECU processes sensor data, it sends commands to various actuators that control engine functions. These output devices transform digital signals into mechanical actions.

- Fuel Injectors represent your ECU's most direct control over engine power. Modern injectors can pulse dozens of times per second, delivering precisely metered fuel quantities based on ECU calculations. The timing, duration, and pressure of each injection directly affects combustion quality, power output, and emissions levels.

- Ignition Coils receive ECU commands to fire spark plugs at precisely calculated moments. Timing is everything here. Fire the spark too early or too late, and you'll experience reduced power, increased emissions, or engine damage. Modern coil-on-plug systems allow individual cylinder control for optimal performance.

- Idle Air Control (IAC) Valves maintain stable idle speeds by regulating airflow when your throttle is closed. The ECU constantly adjusts IAC valve position to compensate for engine load changes from accessories like air conditioning or power steering. A faulty IAC valve causes erratic idle speeds and stalling.

- Variable Valve Timing (VVT) Actuators allow the ECU to optimize valve timing for different operating conditions. During low-speed operation, the ECU might advance timing for better torque. At high speeds, it may retard timing for increased power. This dynamic adjustment improves both performance and fuel economy.

How ECUs Talk to Each Other

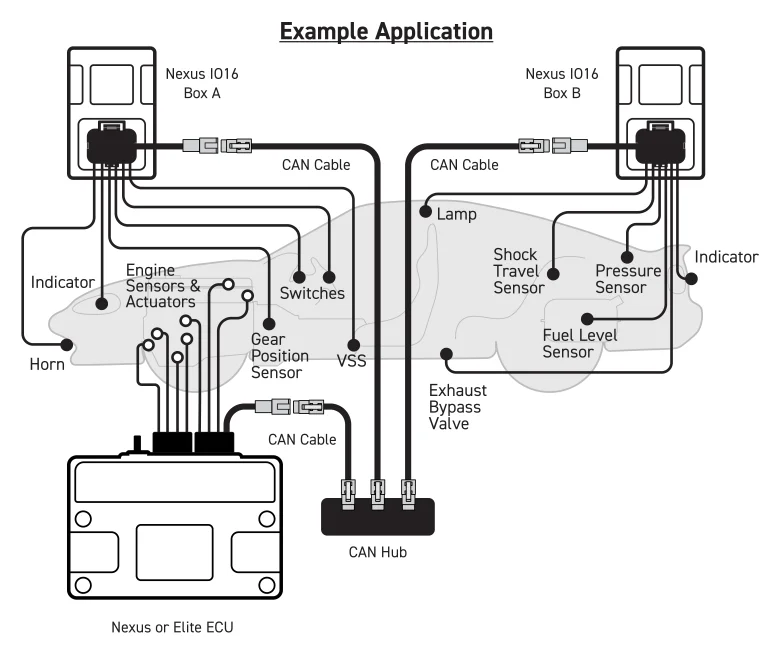

Modern vehicles don't rely on a single ECU making isolated decisions. Multiple control units communicate through the Controller Area Network (CAN bus), creating an integrated system where different modules share critical information.

Your engine ECU communicates with transmission control units to coordinate gear changes with engine power delivery. It shares data with anti-lock braking systems to cut engine power during emergency stops. Climate control systems receive engine temperature data to manage cabin heating efficiently.

This network approach allows for sophisticated vehicle responses that wouldn't be possible with standalone systems. When you're climbing a steep hill, your ECU might communicate with the transmission to hold lower gears longer while adjusting fuel delivery for maximum torque.

When Things Go Wrong

Your ECU continuously monitors system health through built-in diagnostic routines. When sensors provide readings outside normal parameters, the ECU logs diagnostic trouble codes (DTCs) and often illuminates your check engine light.

These self diagnostic capabilities have revolutionized automotive troubleshooting. Technicians can connect scan tools to retrieve specific error codes that pinpoint problem areas. Rather than guessing at potential causes, modern diagnostics provide targeted information about failing sensors, actuator problems, or system malfunctions.

The ECU also runs continuous self-tests on critical systems. If a sensor fails, backup strategies often keep your engine running in "limp mode" until repairs can be made. This fail safe approach prevents catastrophic damage while maintaining basic transportation capability.

ECU Evolution Continues

As vehicles become more sophisticated, ECU capabilities continue expanding. Adaptive learning algorithms allow modern ECUs to adjust strategies based on your driving patterns and environmental conditions. Some systems can even compensate for engine wear over time, maintaining optimal performance throughout your vehicle's lifespan.

Electric and hybrid vehicles are pushing ECU development in new directions. Battery management, regenerative braking coordination, and electric motor control require different expertise than traditional engine management. Yet the fundamental principles remain the same: sensors provide data, processors make calculations, and actuators execute commands.

Understanding your ECU's role in vehicle operation empowers you to make informed maintenance decisions and communicate effectively with automotive professionals. Whether you're troubleshooting performance issues or simply wanting to understand how your car works, ECU knowledge provides valuable insights into modern automotive technology.

The next time you turn your key or push your start button, remember the incredible computational power working behind the scenes. Your ECU stands ready to process thousands of variables, make split-second decisions, and deliver the precise engine control that makes modern driving possible. It's automotive engineering at its finest, hidden in plain sight under your hood.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion