Nearly 30% of roadside assistance calls in North America involve cooling system failures, yet here you are, radiator replaced, thermostat swapped, water pump installed, watching that temperature gauge climb into the red zone again.

"I fixed everything!" That's what I hear from frustrated customers almost weekly. The brutal truth? Your expensive repair bill may have missed the real culprit entirely.

After diagnosing several overheating engines, I've learned that the most obvious problems often mask deeper issues. Your mechanic replaced the usual suspects, but your engine is still running hotter than a summer sidewalk. Let's dig into why this happens and what you can actually do about it.

The Hidden Enemy

Here's something that'll make you want to bang your head against the steering wheel. The number one reason engines overheat after cooling system repairs isn't a bad part, it's trapped air. When your cooling system gets opened up for repairs, air sneaks in like an uninvited guest at a barbecue.

These air pockets create what we call "vapor locks." Think of it like trying to drink through a straw with holes in it. Your coolant can't circulate properly because air bubbles are blocking the flow. I've seen brand new water pumps fail to cool engines because nobody properly bled the system afterward.

The proper bleeding procedure isn't rocket science, but it requires patience. Your engine needs to run at operating temperature with the radiator cap off, allowing trapped air to escape through the highest point in the system. Many shops rush this step or skip it entirely. Result? You're back on the road with an expensive cooling system that doesn't actually cool.

When Good Parts Go Bad (Or Were Never Good)

"But I bought the premium thermostat!" Sure you did. But here's a reality check that might sting a little, not all replacement parts are created equal. I've tested brand new thermostats that stick closed at temperatures nowhere near their rated opening point.

Your thermostat might be the wrong temperature rating entirely. Modern engines are engineered to run at specific temperatures, typically between 195°F and 220°F. Install a 180°F thermostat in an engine designed for 200°F operation, and you've created a mismatch that confuses the computer and can actually cause overheating.

Water pumps present their own challenges. Cheap aftermarket pumps often have impellers that don't match the original specifications. The clearances are wrong, the blade angles are off, or the materials can't handle the pressure. I've pulled apart "new" water pumps that looked like they'd been chewed up by a garbage disposal after just a few thousand miles.

The Radiator That Isn't Really Fixed

Your mechanic says the radiator is "fine" because it's not leaking. But fine and functional are two different things entirely. Internal blockages don't announce themselves with dramatic coolant puddles under your car.

Mineral deposits, stop leak products from previous repairs, and debris can create partial blockages that restrict coolant flow. Your radiator might pass 60% of the coolant it should, which works great at idle but fails miserably when you're climbing hills or stuck in traffic.

Testing requires more than a visual inspection. Flow testing or thermal imaging can reveal restrictions that aren't visible to the naked eye. Many shops don't have this equipment or don't take the time to use it properly.

The Cooling System Investigation You Need

Stop throwing parts at the problem and start investigating like a detective. Here's what actually works:

- Temperature differential testing tells the real story. Measure coolant temperature going into the radiator versus coming out. If the difference is less than 15 - 20°F at operating temperature, your radiator isn't doing its job. If there's no temperature difference at all, coolant isn't flowing properly.

- Check your cooling fans. They should kick on when coolant reaches about 220°F. If they're not running, or running at the wrong speed, your radiator can't dissipate heat properly. Electric fan motors fail gradually, spinning slower each month until they're barely moving air.

- Verify your radiator cap pressure rating. The wrong cap can cause overheating that looks exactly like a failed cooling system. A 13 PSI cap on a system designed for 16 PSI won't maintain proper coolant flow at higher temperatures.

When Professional Help Actually Helps

Not every overheating problem requires a PhD in thermodynamics, but some do. If you've properly bled the system, verified all components are correct for your vehicle, and still can't solve the problem, it's time for professional diagnosis.

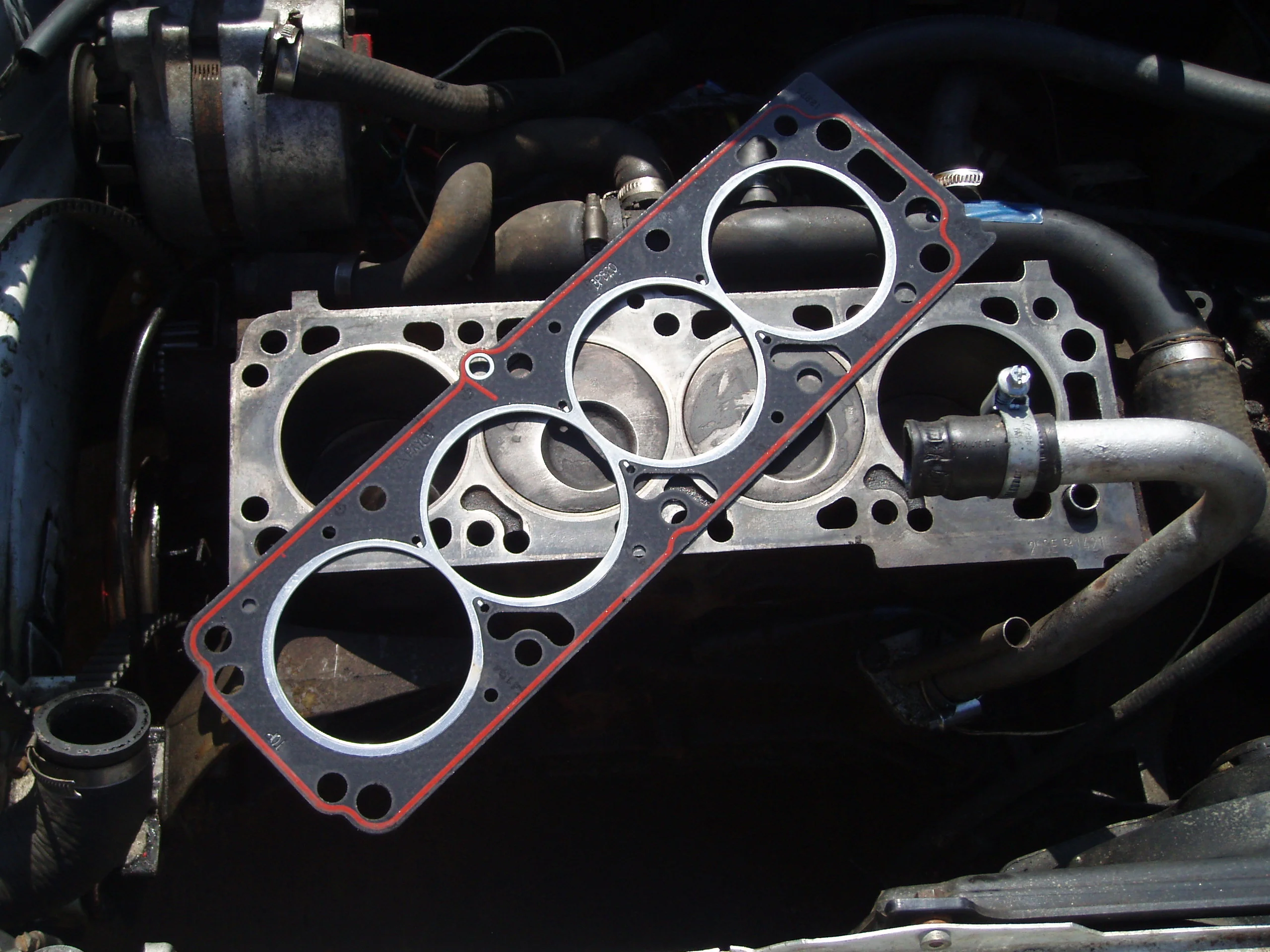

Combustion leak testing can reveal internal engine problems that masquerade as cooling system failures. A blown head gasket or cracked cylinder head will defeat any cooling system repair. These problems require specialized equipment to diagnose properly.

Computer diagnostic tools can reveal cooling system problems that aren't obvious during visual inspection. Modern vehicles monitor coolant temperature, flow rates, and fan operation continuously. The diagnostic data often points directly to the real problem.

Your engine's cooling system is more complex than most people realize. When repairs fail to solve overheating problems, the issue usually isn't mechanical failure, it's incomplete diagnosis or improper installation procedures. Take the time to investigate thoroughly before spending more money on parts that won't fix the real problem.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion