Picture this: You're cruising down the highway at 65 mph, the engine purring at a comfortable 3,000 RPM in fifth gear. Suddenly, in a moment of mechanical misfortune, your hand finds first gear instead of third.

In racing circles, they call this a “money shift”, and for good reason: it can cost you thousands in engine repairs.

Every automotive technician has heard the horror stories. I've seen engines that went from perfectly healthy to scrap metal in the span of two seconds. The physics are brutal, the consequences expensive, and the prevention surprisingly simple once you understand what's happening under the hood.

The Mathematics of Mechanical Mayhem

When you shift into first gear at highway speeds, you're asking your engine to do the impossible. Let's crunch the numbers.

Your typical car traveling at 65 mph in fifth gear might be running at 2,800 RPM. That's comfortable territory. But force that same 65 mph through first gear, and you're demanding your engine spin at approximately 9,700 RPM, nearly three times the redline of most passenger vehicles.

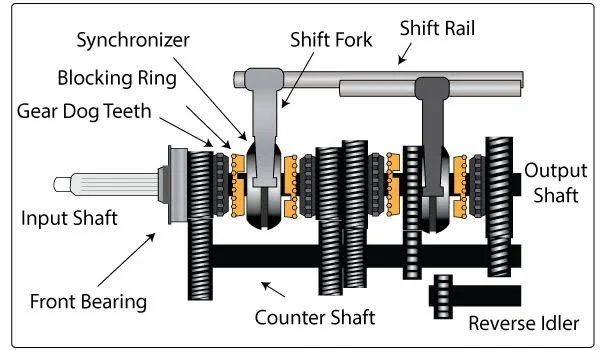

The transmission doesn't care about your engine's mechanical limits. It will attempt to match wheel speed to gear ratio regardless of the consequences. Modern synchronizers, those clever little friction devices that smooth out gear changes, will try their best to equalize the speeds, but they're fighting a losing battle against physics.

"I know my transmission can handle anything," drivers often tell me before learning this expensive lesson. The harsh reality? No transmission was designed for such extreme speed differentials.

The Synchronizer's Desperate Last Stand

Manual transmissions rely on synchronizers to make gear changes smooth and effortless. These bronze and steel rings use friction to match the speed of the gear you're selecting to the speed of the output shaft. Under normal conditions, they're mechanical marvels that work flawlessly for hundreds of thousands of miles.

During a money shift, synchronizers face impossible odds. According to research from TREMEC, a leading transmission manufacturer, synchronizers can handle reasonable speed differences through their multi cone design, which increases friction surface area for faster speed matching. However, when you're asking them to bridge a gap of 6,000+ RPM, they're operating far beyond their design parameters.

The result? Synchronizer rings can overheat, warp, or shatter entirely. Even if they survive the initial shock, they'll likely suffer permanent damage that affects future shift quality.

The Engine's Breaking Point

The real carnage happens inside your engine. At extreme RPM levels, valve float becomes a critical concern. Your engine's valves are held closed by springs that must compress and decompress rapidly as the camshaft rotates. These springs are calibrated for specific RPM ranges, typically up to around 7,000 RPM in performance engines, less in economy cars.

Above these limits, the springs can't keep up. The valves lose control, staying open when they should be closed. This creates a perfect storm for catastrophic failure: pistons traveling upward can collide with open valves, bending or breaking both components.

Engineering Explained's Jason Fenske experienced this firsthand in a Nissan Z at a track event. When he accidentally shifted from third to second at redline, the engine would have needed to spin at 9,724 RPM to maintain the same road speed, 43% above the car's redline.

The immediate symptoms are unmistakable: violent deceleration, possible loss of control, and often a cloud of smoke from the exhaust as oil burns in cylinders where valve seals have failed.

Your Electronic Guardian Angel

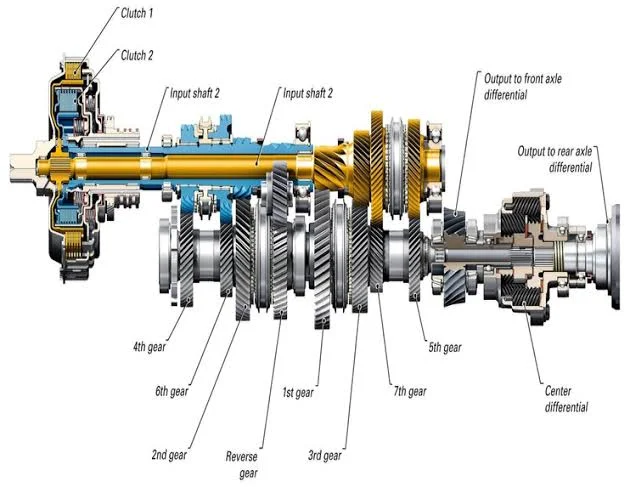

"My automatic will protect me from this," many drivers assume, and they're largely correct. Modern automatic transmissions incorporate sophisticated fail-safe mechanisms that monitor vehicle speed, engine RPM, and throttle position continuously.

These systems use multiple sensors and control modules to prevent dangerous downshifts. When you manually select a lower gear using paddle shifters or the gear selector, the transmission control unit performs split-second calculations to determine if the requested shift is safe. If it would cause engine over-rev, the system simply ignores your input.

Some luxury manufacturers go even further. The transmission may allow a partial downshift to an intermediate gear that won't damage the engine, or it may delay the shift until vehicle speed decreases to a safe level.

The Innovation Race

BMW recently filed patents for an intriguing solution to money shift prevention in manual transmissions. Their proposed system uses lock out mechanisms, similar to existing reverse lockouts, that physically prevent selection of gears that would cause engine damage at current speeds.

The system monitors either crankshaft speed and current gear selection, or vehicle speed directly, then blocks access to dangerous gear gates. As speed decreases, previously blocked gears become available again. It's brilliant in its simplicity, mechanical protection for mechanical mistakes.

This innovation addresses a real market need. BMW's N55 and S55 engines are particularly vulnerable to spun crank hubs during over-rev events, creating expensive warranty claims and customer dissatisfaction.

The Cost of Speed

The financial impact of a money shift varies dramatically based on engine design and how quickly you recognize the mistake. Minor cases might require only new valve seals and a timing belt replacement, perhaps $800 to $1,500 in repairs.

Severe cases can destroy the entire top end of your engine. Bent valves, damaged pistons, broken connecting rods, and scored cylinder walls can push repair costs into the $8,000 - $15,000 range. In some cases, complete engine replacement becomes the only viable option.

The psychological impact shouldn't be underestimated either. I've worked with drivers who developed anxiety about manual transmissions after a money shift experience, ultimately trading their cars for automatics despite previously being enthusiastic stick-shift advocates.

Your Three Lines of Defense

- First, develop consistent shifting patterns. Use the same hand positions and movements every time you shift. Muscle memory is your best defense against selecting the wrong gear under stress.

- Second, practice rev matching on downshifts. This technique not only reduces wear on synchronizers but also makes incorrect gear selection immediately obvious through engine sound and feel.

- Third, never rush shifts during aggressive driving. Whether on track or navigating challenging mountain roads, smooth deliberate inputs prevent costly mistakes. "Speed comes from smoothness," as racing instructors often say.

Shifting to first gear at high speed transforms your transmission from a precision instrument into a mechanical grenade. The physics are unforgiving, the consequences expensive, and the prevention entirely within your control.

Understanding these principles makes you a better, more confident driver. Respect your transmission's limits, develop good shifting habits, and remember that the most expensive mistake is the one you could have easily avoided.

Your engine, and your wallet will thank you for the caution.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion