Picture this: You've filled up your tank to the brim, heard that satisfying click of the gas pump, yet your dashboard mockingly displays a glowing low fuel warning light.

According to AAA research, 74% of drivers rely on their fuel gauge displays to decide when to fill up, but what happens when that trusted indicator lies to you? This maddening contradiction between reality and dashboard readings affects thousands of drivers monthly, and it's more common than you might think.

"I know my tank is full because I watched the attendant fill it," drivers often protest to mechanics. Yet their gauge tells a different story entirely.

Let me walk you through exactly what's happening under your hood and how to fix it.

The Fuel Gauge System

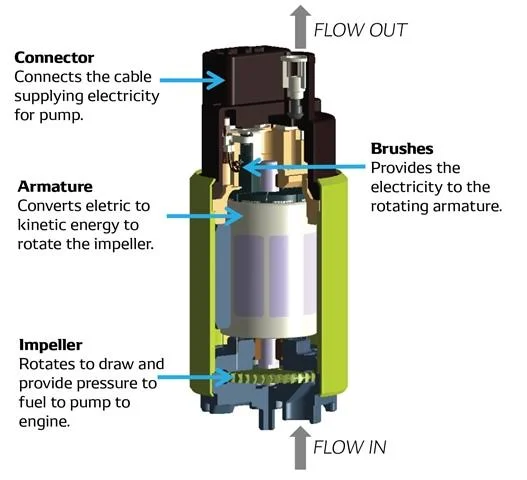

Your fuel gauge isn't some mystical device that magically knows how much gas you have. It operates through a surprisingly simple yet precise system that can fail in frustrating ways.

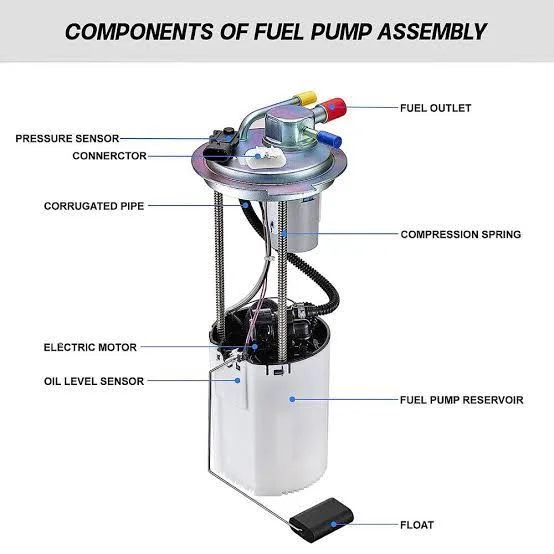

The heart of the system is the fuel sending unit, located inside your gas tank. This unit contains a float arm that rises and falls with your fuel level, much like a toilet float. As the float moves, it changes the resistance in an electrical circuit, sending different voltage signals to your dashboard gauge.

When everything works perfectly, you get accurate readings. When it doesn't? That's when you get the dreaded full tank empty gauge scenario that brought you here.

Three Primary Causes Behind Your Gauge Problems

The Fuel Sending Unit Failure

This is the heavyweight champion of fuel gauge problems. The sending unit takes a beating inside your fuel tank, constantly moving, exposed to fuel chemicals, and dealing with temperature changes. Over time, the float can stick, the resistance track can wear out, or the wiper arm can break.

Signs your sending unit is failing include erratic gauge behavior, readings that jump between full and empty, or a gauge permanently stuck in one position. According to automotive repair data, sending unit problems account for roughly 80% of fuel gauge malfunctions.

Electrical Gremlins in the Wiring

Corroded connections and damaged wiring create havoc with gauge accuracy. These problems often develop gradually, you might notice your gauge working intermittently before failing completely. Water damage, road salt, and simple age can corrupt the electrical pathways between your tank and dashboard.

Check your owner's manual for fuse locations. A blown fuel gauge fuse is one of the easiest fixes you'll ever encounter in automotive repair.

Instrument Cluster Malfunction

Sometimes the problem isn't in the tank at all, it's right there on your dashboard. Modern instrument clusters are sophisticated electronic modules that can develop internal faults. If multiple gauges act up simultaneously, you're likely dealing with a cluster problem rather than individual sensor failures.

DIY Diagnosis

Start with the obvious stuff before diving deep. Pop your hood and locate the fuel gauge fuse, it's usually in the main fuse box and clearly labeled in your owner's manual. A visual inspection takes thirty seconds and might save you hundreds in diagnostic fees.

Next, pay attention to patterns. Does your gauge work sometimes but not others? Does tapping the dashboard make any difference? These behaviors provide crucial clues about whether you're dealing with loose connections, intermittent failures, or complete component death.

"My gauge worked fine yesterday, but today it's completely dead," is a common complaint that often points to electrical issues rather than mechanical failure.

Professional Repair

When DIY approaches fall short, professional diagnosis becomes necessary. Modern shops use specialized equipment to test sending unit resistance and check voltage signals throughout the fuel gauge circuit.

Expect diagnostic fees ranging from $100-150 at most reputable shops. This investment pays off because accurate diagnosis prevents throwing parts at the problem, a costly mistake many car owners make.

If your sending unit needs replacement, brace yourself for the bill. Labor costs typically run $229-336, while parts range from $1,100-1,300 depending on your vehicle. The high labor cost reflects the complexity of accessing components inside your fuel tank, which often requires dropping the entire tank or removing your back seat.

Prevention

Regular maintenance prevents most fuel gauge problems. Keep your tank at least quarter-full to reduce sending unit wear from constant movement in an empty tank. Quality fuel helps too, cheap gas with high ethanol content can accelerate sending unit deterioration.

Annual electrical system checks catch wiring problems before they strand you with an unreliable gauge. Many drivers ignore minor gauge inconsistencies until complete failure occurs, turning a $200 repair into a $1,500 ordeal.

Fuel gauge problems rarely fix themselves, and ignoring them creates bigger headaches down the road. Whether you're dealing with a simple fuse replacement or a complete sending unit overhaul, accurate diagnosis saves money and prevents frustration.

Don't let a lying fuel gauge control your driving decisions. Address the problem systematically, and you'll restore confidence in your dashboard readings. After all, you shouldn't have to guess how much fuel you have when technology exists to tell you precisely.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion