According to a study by the Automotive Transmission Rebuilders Association, nearly 35% of electronically controlled transmission failures stem directly from solenoid malfunction.

Yet many drivers wouldn't recognize these critical components if they were sitting right in front of them. After diving deep into transmission technology research, I can tell you this: understanding these parts can save you thousands in repair costs and countless roadside headaches.

Understanding the Transmission's Nervous System

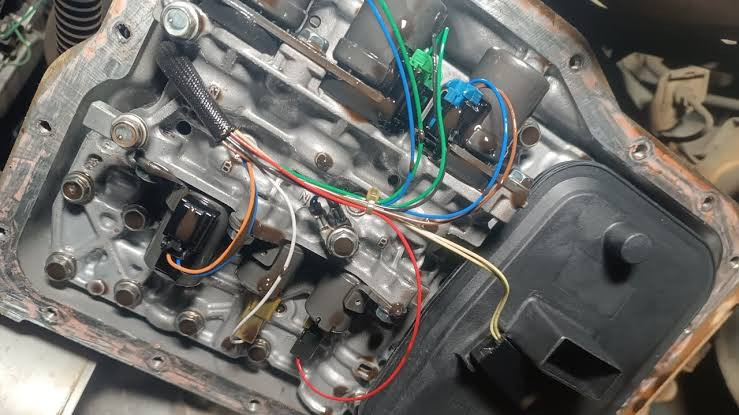

Your automatic transmission contains a very complicated hydraulic control center, the valve body and a series of electromagnetic switches called solenoids that work together like your vehicle's nervous system.

Transmission solenoids are electro-hydraulic valves that control the flow of transmission fluid through the valve body based on signals from your vehicle's computer. As one transmission expert explains: "The solenoid coil consists of wire wound around a conductive component that acts as an electronic magnet, controlling the valve's position".

The valve body itself is "filled with valves, passages, and solenoids that divert transmission fluid to where it's supposed to go" within the transmission system. Think of it as a complex hydraulic circuit board with multiple channels and control points.

When functioning properly, this system creates seamless gear transitions. When failing, your driving experience becomes unpredictable and potentially dangerous.

Warning Signs: Your Transmission is Crying for Help

Your vehicle communicates solenoid and valve body problems through specific symptoms:

- Delayed shifting: According to transmission specialists, "If you experience a delay in shifting, or your vehicle has ever jumped to another gear on its own, there is a very good chance that one or more solenoids are failing".

- Harsh shifts: Feeling a pronounced "clunk" when changing gears indicates pressure regulation problems in the valve body.

- Transmission slipping: If engine RPMs increase without a corresponding speed increase, your solenoids may not be properly controlling fluid pressure.

- Getting stuck in gear: A damaged solenoid can leave your transmission unable to shift out of a particular gear.

- Illuminated warning lights: Modern vehicles typically trigger the check engine light for solenoid issues, often resulting in diagnostic trouble codes P0750 - P0770.

Research shows these symptoms shouldn't be ignored. A study from the International Journal of Automotive Engineering found that minor solenoid issues can escalate to major transmission damage within as little as 5,000 miles of continued operation.

What Causes Solenoid and Valve Body Failures?

Several factors lead to these critical transmission components failing:

Contaminated Transmission Fluid

The primary cause: Research indicates that nearly 65% of solenoid failures result from contamination due to irregular fluid changes. Metal particles, dirt, and degraded fluid can clog solenoid passages and valve body channels.

"Dirty transmission fluid may cause the shift solenoid to become stuck open or closed," preventing proper operation.

Electrical Issues

Modern transmissions rely on precise electrical signals. A short circuit, corroded wiring, or failing Transmission Control Module (TCM) can cause solenoid malfunction even when the mechanical components are sound.

Heat Damage

Excessive heat is the silent transmission killer. Operating temperatures above 200°F can rapidly degrade transmission fluid, which then loses its lubricating and hydraulic properties. This creates a destructive cycle: poor lubrication leads to increased friction, which raises temperatures further.

Normal Wear and Tear

Like any mechanical component, solenoids and valve bodies have a lifespan. The solenoids' electromagnetic coils can weaken over time, and valve body bores can wear, causing valves to stick.

DIY Diagnosis: Is It Your Solenoids?

Before heading to a repair shop, perform these basic diagnostic checks:

Transmission Fluid Check

- Park on level ground with the engine warmed up and running.

- Locate the transmission dipstick (consult your owner's manual).

- Remove it, wipe clean, reinsert, and check again.

- Note both the fluid level and condition.

Healthy transmission fluid should be bright red and translucent. Dark fluid with a burnt smell or visible particles strongly indicates valve body issues affecting your shifting.

Scan for Trouble Codes

Use an OBD-II scanner to check for transmission-related codes. Codes in the P0750 - P0770 range specifically indicate solenoid circuit problems. This diagnostic step can save hours of guesswork and narrow down which specific solenoid may be failing.

Solution Spectrum: From Simple to Complex

Transmission Fluid Service (DIY Cost: $50 - 150)

A complete fluid change with filter replacement can sometimes resolve minor solenoid issues by removing contaminants causing sticking. Follow these steps for a DIY approach:

- Purchase the correct transmission fluid for your specific vehicle model.

- Locate the transmission pan and drain plug.

- Place a large drain pan underneath and remove the plug.

- Once drained, remove the transmission pan bolts carefully.

- Replace or clean the transmission filter.

- Reinstall the pan with a new gasket.

- Refill with new fluid following manufacturer specifications.

For many vehicles, transmission fluid should be changed every 30,000 - 60,000 miles, though some manufacturers claim "lifetime" fills (a claim many transmission specialists dispute).

Individual Solenoid Replacement (DIY Cost: $50 - 300 per solenoid)

If diagnostics point to a specific faulty solenoid:

- Locate your transmission's solenoid pack (usually requires partial transmission disassembly).

- Disconnect the electrical connector.

- Remove mounting bolts and extract the solenoid.

- Replace with a new part, ensuring proper alignment.

- Reassemble and clear trouble codes.

According to AutoNation Mobile Service, replacing a single faulty transmission solenoid costs approximately $250 professionally, while replacing an entire solenoid pack runs around $400.

Valve Body Rebuild or Replacement (Professional Cost: $400-3,500)

For severe valve body issues, professional service is typically required due to the precision needed:

- Complete transmission pan removal

- Valve body removal and disassembly

- Thorough cleaning of all passages and valves

- Replacement of worn components

- Precise reassembly following manufacturer specifications

"Replacing a faulty transmission valve body can cost between $400 and $3,500," with parts ranging from $100 to $2,500 and labor from $300 to $1,000.

TCM Reprogramming (Professional Cost: $75 - 300)

Sometimes the issue isn't mechanical but electronic. Updated software for your transmission control module can resolve shifting issues by adjusting solenoid timing and pressure parameters.

Prevention: The Best Medicine for Your Transmission

Implementing these preventive measures can significantly extend solenoid and valve body life:

- Change transmission fluid regularly: Most experts recommend every 30,000 - 60,000 miles, despite some manufacturers claiming "lifetime" fluid.

- Use the correct fluid type: Using incorrect fluid can damage seals and solenoids. Always follow manufacturer specifications.

- Install a transmission cooler: These relatively inexpensive devices can reduce transmission operating temperatures by 20 - 30%, dramatically extending fluid life and component durability.

- Address issues promptly: Minor shifting issues can quickly cascade into major problems. When you first notice transmission irregularities, don't wait for them to "fix themselves."

- Drive sensibly: Aggressive driving with rapid acceleration and hard braking puts additional stress on transmission components.

According to the transmission specialists at Mister Transmission, regular maintenance can dramatically reduce transmission failure rates: "Regular fluid service can offset or reduce wear and extend the service life of your solenoids".

When to Call a Professional

While DIY approaches work for many solenoid issues, seek professional help if you experience:

- Multiple transmission-related trouble codes

- Metal particles in your transmission fluid

- Complete failure to shift gears

- Recurring solenoid failures despite replacement

Modern transmissions are incredibly complex systems. Professional transmission shops have specialized diagnostic equipment that can identify root causes with precision, potentially saving you from multiple repair attempts.

Conclusion

Solenoid and valve body issues don't have to mean complete transmission replacement. Understanding these components and recognizing their warning signs gives you powerful options for addressing problems before they escalate.

Whether it's regular fluid maintenance, targeted solenoid replacement, or professional valve body rebuilding, addressing these issues promptly can extend your transmission's life by years and save thousands in repair costs.

I've seen the data: proper maintenance of transmission hydraulics dramatically reduces failure rates. Your transmission isn't just asking for attention, it's demanding it. Listen carefully, and it will reward you with thousands of miles of smooth, reliable shifting.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion