Modern vehicles equipped with direct injection systems can lose up to 25% of their power output due to carbon buildup on intake valves within 60,000 miles of driving.

This statistic from the Automotive Service Association represents one of the most overlooked maintenance issues plaguing today's fuel efficient engines.

Fuel injection technology revolutionized automotive performance and efficiency. Gone are the days of finicky carburetors and poor fuel economy. Today's direct injection systems deliver precise fuel metering, improved combustion, and enhanced power output that would have seemed impossible decades ago.

But this technological advancement comes with a hidden cost that many drivers discover too late. Carbon buildup on intake valves has become the silent performance killer in modern engines, creating a maintenance challenge that didn't exist in previous generations of vehicles.

I've witnessed countless drivers experience mysterious power loss, rough idle, and poor fuel economy without realizing their intake valves were slowly choking their engine's ability to breathe. This problem affects vehicles across all price ranges, from economy cars to luxury performance machines.

Understanding the Root Cause

Direct injection systems spray fuel directly into the combustion chamber rather than into the intake ports like traditional port injection systems. This design improvement delivers better fuel atomization and more precise timing control, resulting in increased power and efficiency.

However, this efficiency gain creates an unexpected consequence. In port injection systems, gasoline flowing over the intake valves provided a natural cleaning effect, washing away carbon deposits and keeping the valves relatively clean throughout the engine's life.

Direct injection eliminates this cleaning action entirely. Without gasoline flowing over the intake valves, carbon deposits accumulate from crankcase ventilation gases and combustion byproducts that find their way into the intake system.

The buildup process happens gradually over thousands of miles. Microscopic carbon particles stick to the hot intake valve surfaces, creating a foundation for additional deposits. Over time, these deposits grow thicker and more stubborn, eventually restricting airflow into the combustion chamber.

Recognizing the Warning Signs

Carbon buildup symptoms often develop so gradually that drivers adapt to declining performance without realizing their vehicle has a problem. The most common indicators include:

- Reduced power output: Your engine feels sluggish during acceleration, particularly when climbing hills or merging onto highways. The throttle response becomes delayed, and the engine struggles to reach higher RPMs smoothly.

- Rough idle: The engine develops an irregular idle pattern, with RPMs fluctuating or the engine feeling like it's about to stall when stopped at traffic lights. This symptom becomes more pronounced when the air conditioning or other electrical loads are engaged.

- Poor fuel economy: Despite driving habits remaining consistent, fuel consumption increases noticeably. The engine computer compensates for restricted airflow by adding more fuel, reducing overall efficiency.

- Engine knock: Carbon deposits create hot spots in the combustion chamber that can cause premature ignition, resulting in a knocking or pinging sound under acceleration.

- Check engine light: Advanced carbon buildup can trigger diagnostic trouble codes related to fuel trim, oxygen sensor readings, or misfire detection.

The Inspection Process

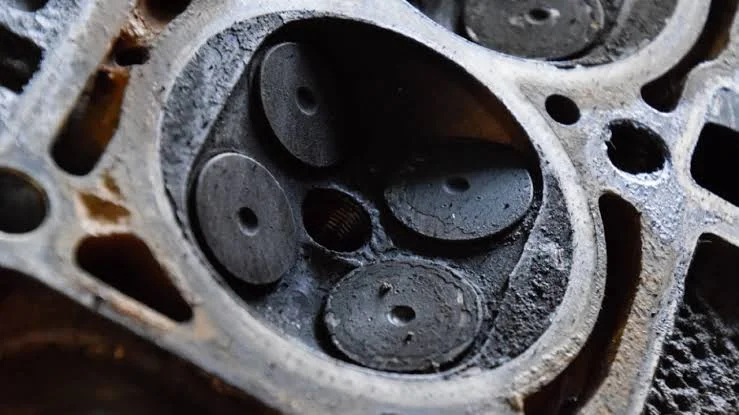

Professional diagnosis requires specialized equipment that most DIY mechanics don't possess. Technicians use borescopes to visually inspect intake valves through spark plug holes or intake manifold openings.

The inspection reveals the extent of carbon accumulation on valve surfaces. Light deposits appear as dark discoloration on the valve stems and heads. Severe buildup creates thick, crusty deposits that significantly reduce the valve's ability to seal properly against its seat.

Digital imaging during borescope inspection provides before-and-after documentation that helps vehicle owners understand the severity of their engine's condition. This visual evidence often surprises owners who had no idea their engine harbored such extensive deposits.

Professional Cleaning Methods

- Walnut blasting: This method uses crushed walnut shells propelled by compressed air to remove carbon deposits mechanically. Technicians remove the intake manifold to access the valves directly, then blast each valve individually while protecting the combustion chamber from debris. The walnut shell media is soft enough to avoid damaging valve surfaces while being abrasive enough to remove stubborn carbon deposits. The process typically takes 4 - 6 hours and costs between $400 - 800 depending on engine complexity.

- Chemical cleaning: Professional grade solvents designed specifically for carbon removal can dissolve deposits without mechanical scrubbing. This method works well for moderate buildup but may not be effective against heavily carbonized valves. Chemical cleaning requires the engine to be warmed to operating temperature, then specialized cleaning solutions are introduced through the intake system while the engine runs at specific RPMs. The process takes 1 - 2 hours and costs $200 - 400.

- Combination approach: Many shops use both walnut blasting and chemical cleaning to achieve optimal results. The chemical treatment softens deposits, making mechanical removal more effective and thorough.

Prevention Strategies That Actually Work

- Quality fuel Selection: Top tier gasoline brands contain higher concentrations of detergent additives that help minimize carbon formation. While these fuels cost more per gallon, the long-term engine protection often justifies the expense. Research from AAA demonstrates that top tier gasoline can reduce carbon deposits by up to 72% compared to minimum standard fuels. Look for brands that display the Top Tier certification logo at the pump.

- Regular high RPM Operation: Engines that rarely exceed 3,000 RPM accumulate carbon faster than those regularly operated at higher speeds. Highway driving allows higher exhaust temperatures that help burn off some carbon deposits naturally. Plan monthly highway trips where you can safely operate your vehicle at sustained higher RPMs for 10 15 minutes. This practice helps maintain valve cleanliness and prevents severe accumulation.

- Fuel system cleaners: Professional grade fuel system cleaners containing polyisobutylamine (PIBA) or polyisobutylene amine (PIBA) can help slow carbon formation. These additives work differently than traditional cleaners by targeting intake valve deposits specifically. Use these cleaners every 5,000 - 7,500 miles according to manufacturer instructions. Avoid over-treating, as excessive detergent concentrations can cause other engine problems.

When to Seek Professional Help

Carbon buildup severity varies significantly between engine designs and driving conditions. Some engines develop problematic deposits within 40,000 miles, while others remain relatively clean past 100,000 miles.

Schedule professional inspection if you notice performance degradation, fuel economy decline, or rough idle symptoms. Early intervention costs significantly less than waiting until carbon deposits cause engine damage or trigger expensive diagnostic procedures.

Engines with severe carbon buildup may require valve replacement if deposits have damaged sealing surfaces. This repair can cost $1,500-3,000 depending on engine complexity and parts availability.

Economic Reality

Preventive carbon cleaning every 60,000 - 80,000 miles costs $400 - 800 but protects against much more expensive engine repairs. Severely carbonized engines may require complete top-end rebuilds costing $3,000 - 5,000.

Insurance companies and extended warranty providers typically exclude carbon buildup damage from coverage, considering it a maintenance-related issue rather than a mechanical failure.

Looking Forward

Automotive manufacturers are developing solutions to address carbon buildup in future engine designs. Some brands now offer dual - injection systems that combine direct injection with port injection to maintain valve cleaning while preserving efficiency benefits.

Until these technologies become widespread, understanding and addressing carbon buildup remains essential for maintaining modern engine performance and longevity.

Regular maintenance, quality fuel selection, and proactive cleaning represent the best defense against this hidden enemy that silently steals your engine's power and efficiency. The investment in prevention pays dividends in maintained performance, fuel economy, and engine longevity.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion