According to recent automotive industry data, electrical system failures topped the list of recalled vehicle components in 2024, affecting 6.3 million vehicles worldwide. That's more cars than the entire population of Denmark experiencing electrical gremlins!

Modern vehicles contain over 40 different electrical systems, from your smartphone charger to the engine management computer. When these systems fail, many drivers panic and immediately think “expensive repair shop visit.”

"My car's electrical system works fine," drivers often declare confidently. Until it doesn't.

The truth is, electrical problems rarely happen overnight. They send warning signals weeks or even months before leaving you stranded. Learning to recognize these early symptoms and follow a systematic diagnostic approach can save you hundreds of dollars in unnecessary repairs and prevent that dreaded roadside breakdown.

This guide will walk you through a professional-grade troubleshooting process that even beginners can master. You'll learn to identify electrical issues before they become major problems, use simple tools to pinpoint the exact cause, and determine when you can safely handle repairs yourself.

Understanding the Warning Signs

Your car communicates electrical problems through multiple channels. Dashboard warning lights represent your vehicle's first line of defense against system failures. The battery warning light, appearing as a small battery symbol, indicates charging system problems that could leave you stranded within minutes or hours.

- Flickering or dimming lights while driving signal voltage irregularities in your electrical system. These symptoms often start subtle. Your headlights might dim slightly when you activate the air conditioning, or interior lights might flicker when starting the engine. Don't ignore these early warnings.

- Engine performance issues frequently stem from electrical problems. Rough idling, hesitation during acceleration, or intermittent stalling can indicate failing sensors, corroded connections, or weak battery voltage affecting fuel injection systems.

- Strange sounds tell their own story. A clicking noise when turning the key usually points to starter motor problems or insufficient battery power. Rapid clicking suggests low battery voltage, while a single loud click often indicates starter solenoid failure.

"I know my vehicle will get me home" is what many drivers think when they see the first warning signs. This overconfidence costs them dearly when electrical failures cascade into multiple system breakdowns.

The Essential Diagnostic Tools You Need

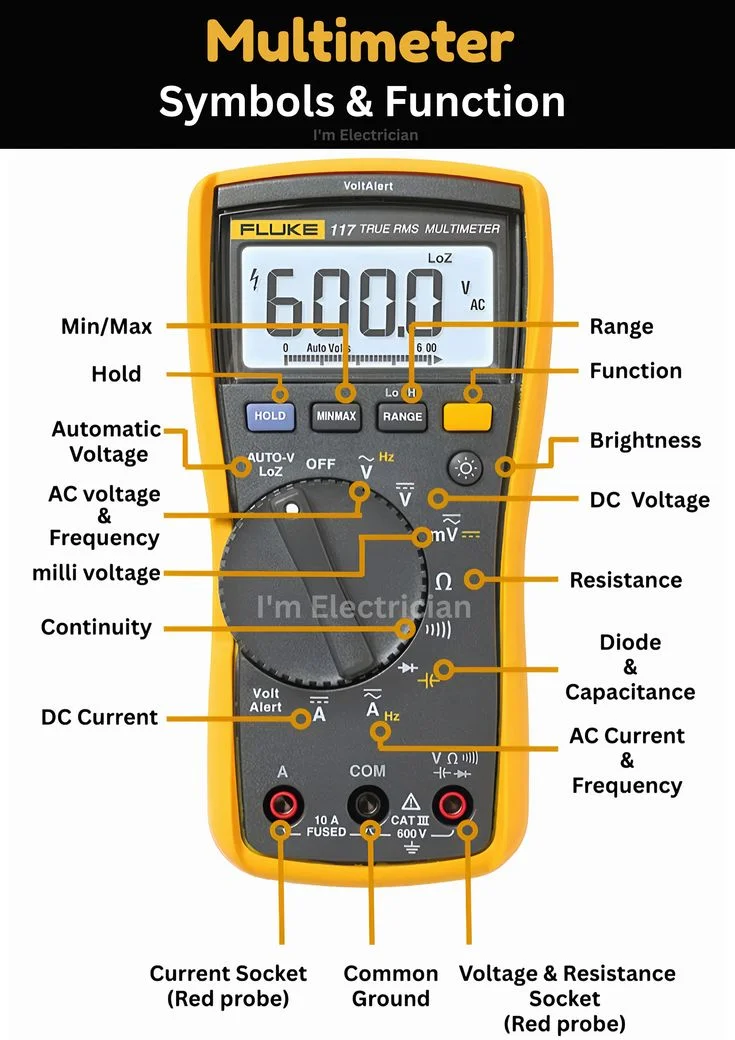

A digital multimeter serves as your primary weapon against electrical mysteries. This tool measures voltage, resistance, and continuity, allowing you to test circuits systematically. Choose a multimeter rated for automotive use with at least 10 megohm input impedance to avoid damaging sensitive electronic components.

Basic hand tools complete your diagnostic arsenal. Wire strippers, electrical tape, and a selection of fuses enable you to address common problems immediately. A flashlight or headlamp provides essential visibility when working in engine compartments or under dashboards.

Safety equipment protects you during electrical work. Insulated gloves prevent shock hazards, while safety glasses shield your eyes from battery acid or flying debris. These items cost less than twenty dollars but prevent serious injuries.

Step by Step Battery Testing Procedure

Start every electrical diagnosis with battery testing. A failing battery masquerades as multiple electrical problems, leading inexperienced technicians down expensive diagnostic rabbit holes.

Set your multimeter to DC voltage mode, typically the 20-volt scale. Connect the red probe to the positive battery terminal and the black probe to the negative terminal. A healthy 12-volt battery should read between 12.4 and 12.7 volts with the engine off.

Perform a load test by starting the engine while monitoring voltage. Battery voltage should not drop below 9.6 volts during cranking. If voltage falls significantly lower, the battery requires replacement regardless of its age.

Check charging system performance with the engine running at idle. Voltage should read between 13.8 and 14.4 volts. Readings below 13.8 volts indicate alternator problems, while readings above 14.4 volts suggest overcharging that damages electrical components.

Visual inspection reveals critical information. Look for white, blue, or green corrosion around battery terminals. Clean corrosion using a wire brush and baking soda solution. Loose battery cables cause intermittent electrical problems that frustrate even experienced mechanics.

Alternator Diagnosis

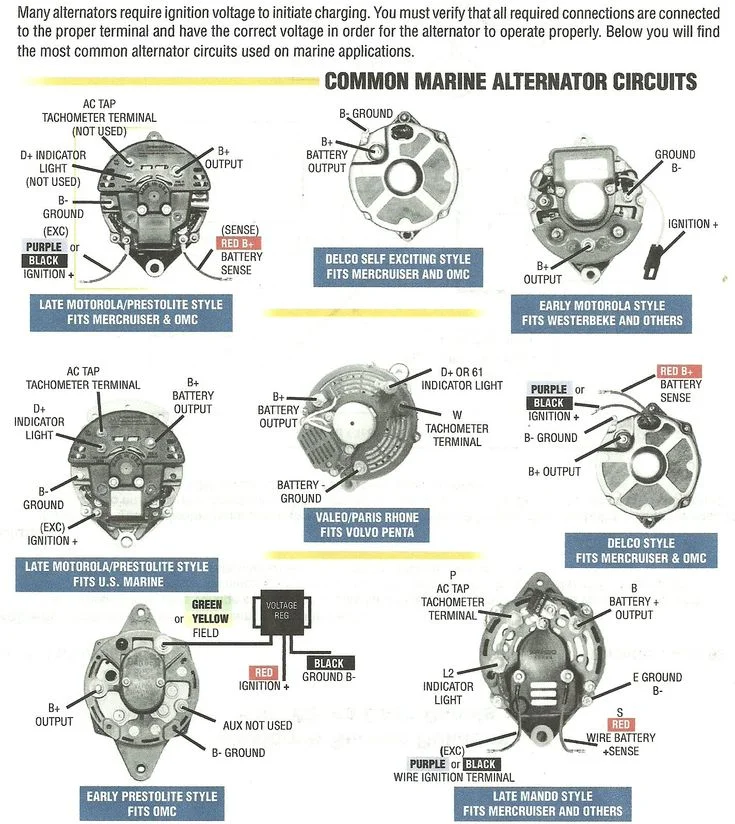

The alternator generates electrical power while your engine runs, making it crucial for vehicle operation. Alternator problems often masquerade as battery issues, creating diagnostic confusion for beginners.

Monitor your dashboard gauges while driving. A voltmeter reading below 13 volts or a battery warning light activation indicates charging system problems. Some vehicles display "ALT" or "GEN" warning lights specifically for alternator issues.

Perform the headlight test for quick alternator assessment. With the engine running at idle, turn on high-beam headlights and observe their brightness. Rev the engine to 2000 RPM and watch for brightness changes. Properly functioning alternators maintain consistent light output regardless of engine speed.

Test alternator output using your multimeter across the battery terminals with the engine running. Voltage should remain steady between 13.8 and 14.4 volts regardless of electrical load. Turn on air conditioning, headlights, and radio while monitoring voltage. Significant voltage drops indicate alternator weakness.

Listen for alternator bearing noise, which sounds like grinding or whining that increases with engine speed. Bearing failure often precedes complete alternator breakdown by several weeks, giving you time to plan repairs.

Starter System Troubleshooting

Starter motor problems prevent engine cranking, leaving drivers stranded in parking lots and driveways. Understanding starter system operation helps distinguish between starter failure and related electrical issues.

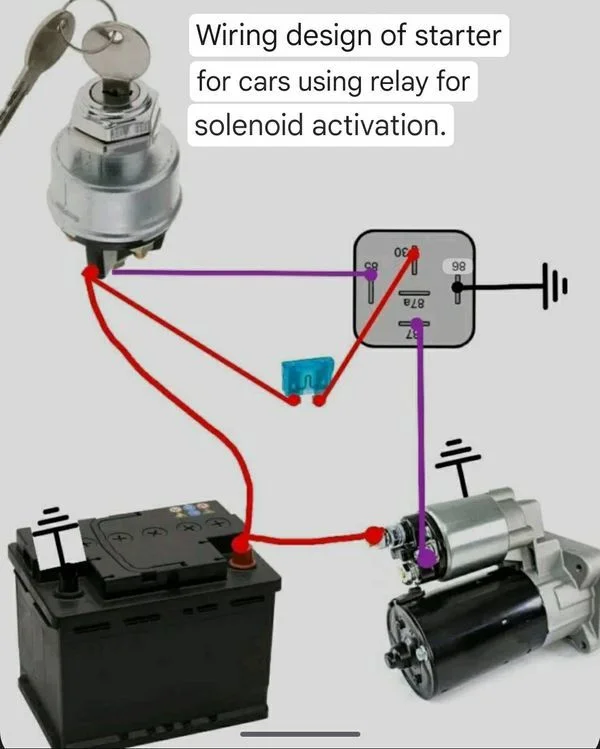

Check battery voltage first, as weak batteries cause most "starter problems." Starter motors require significant electrical current, typically 100-200 amperes during cranking. Insufficient battery power creates symptoms identical to starter failure.

Test starter solenoid operation by listening during key activation. A single loud click indicates solenoid engagement with possible starter motor failure. Rapid clicking suggests insufficient battery voltage reaching the solenoid. Complete silence often points to ignition switch or neutral safety switch problems.

Examine starter connections for corrosion or looseness. The large positive cable carries starting current from the battery, while smaller wires control solenoid activation. Corroded connections create high resistance that prevents adequate current flow.

Professional mechanics use voltage drop testing to identify connection problems. Measure voltage difference between battery positive and starter positive cable during cranking. Readings above 0.5 volts indicate excessive resistance requiring connection cleaning or cable replacement.

When to Seek Professional Help

Recognize the limits of DIY electrical diagnosis. Computer controlled systems require specialized scan tools and software updates beyond typical home mechanics' capabilities. Modern vehicles contain dozens of electronic control modules that communicate through complex networks.

Safety considerations demand professional intervention for certain repairs. High voltage hybrid systems, airbag circuits, and fuel injection wiring require specialized training and equipment. Attempting these repairs without proper knowledge risks serious injury or expensive component damage.

Time and cost factors influence repair decisions. Simple problems like battery replacement or fuse changes save money when performed at home. Complex diagnoses requiring hours of testing often cost less when handled by experienced professionals with proper equipment.

Prevention Strategies That Work

- Regular maintenance prevents most electrical problems. Clean battery terminals monthly using a wire brush and protective spray. Inspect wiring harnesses for signs of wear, especially where they pass through metal openings or near heat sources.

- Keep jumper cables in your vehicle for emergency starting situations. Quality cables with heavy gauge wire and solid connections can start your car when the battery fails unexpectedly. Learn proper jump starting procedures to avoid electrical system damage.

- Address warning signs immediately before they become major problems. That flickering dashboard light or intermittent starting issue will worsen over time. Early intervention typically costs a fraction of emergency repairs.

Building Your Electrical Confidence

Start with simple projects to develop electrical troubleshooting skills. Replace blown fuses, clean battery terminals, and test voltage at various points in your vehicle. Each successful repair builds confidence for tackling more complex problems.

Document your vehicle's normal electrical readings when everything works properly. Recording battery voltage, alternator output, and other key measurements provides baseline data for future comparisons. This information proves invaluable during troubleshooting sessions.

"My mechanic says I need a new wiring harness" is often the last thing drivers want to hear. Understanding basic electrical principles helps you ask intelligent questions and avoid unnecessary repairs. Many "wiring problems" actually stem from simple connection issues that cost pennies to fix.

Modern vehicles challenge even experienced mechanics with their complexity. However, fundamental electrical principles remain unchanged. Voltage must reach components through good connections, circuits must be complete, and proper grounding ensures reliable operation. Master these basics, and you'll solve most electrical problems with confidence.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion