Your turbocharger shaft spins at 300,000 RPM while withstanding exhaust temperatures that can melt window glass.

These mechanical marvels operate under conditions that would destroy most components in seconds, yet drivers often ignore the subtle warning signs that predict catastrophic failure. "My turbo sounds fine to me," they'll say, dismissing that faint whistle as normal operation while their $3,000 component slowly destroys itself from the inside out.

The Engineering Marvel Inside Your Engine Bay

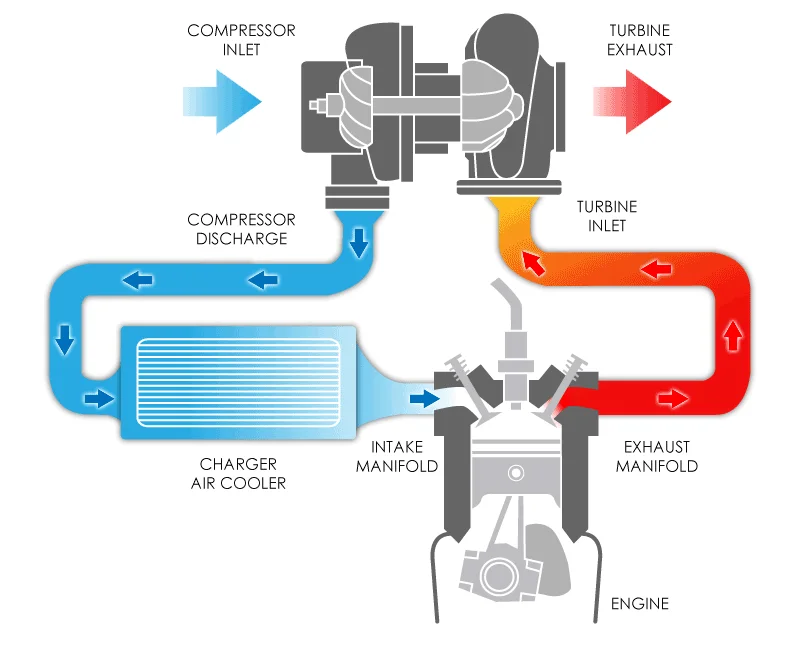

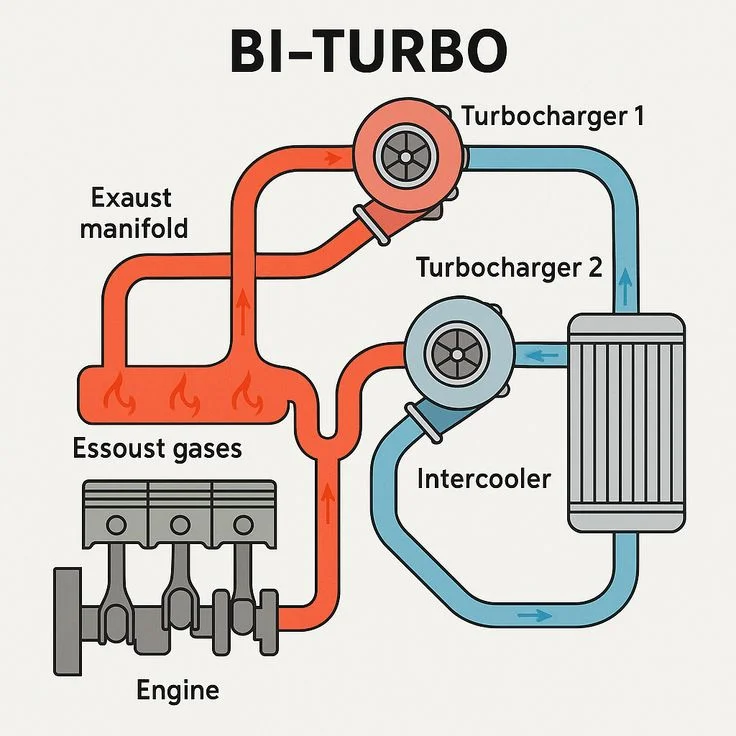

A turbocharger harnesses the violent energy of exhaust gases to force-feed your engine with compressed air. This seemingly simple concept requires precision engineering that borders on the miraculous. The turbine wheel, barely larger than your palm, captures exhaust gases traveling at temperatures exceeding 1,000°C (1,832°F), hot enough to literally melt window glass.

The system consists of two primary sections connected by a shaft thinner than your thumb. The turbine housing captures exhaust energy while the compressor housing forces air into your engine. Between them sits the bearing housing, containing the most critical components you'll never see.

Those bearings must withstand rotational speeds reaching 300,000 RPM, that's 50 times faster than your engine running at 6,000 RPM. At maximum boost, a single turbocharger blade tip moves faster than the speed of sound. The engineering tolerances are so precise that shaft play exceeding 0.004 inches indicates bearing damage requiring immediate attention.

When Whistle Becomes Warning

"It's supposed to make that sound!" This common misconception costs drivers thousands annually. While turbochargers do produce a characteristic whoosh during normal operation, that high-pitched whistle everyone associates with performance actually signals trouble brewing.

A healthy turbo produces a deep whoosh as compressed air flows through the system. The whistle indicates boost leaks, bearing wear, or housing damage. When exhaust gases escape through worn seals or cracked housings, they create that distinctive high-pitched sound that drivers mistake for normal operation.

The most dangerous sounds emerge gradually. That barely perceptible whine during acceleration grows louder over weeks or months. By the time you notice it clearly, internal damage has already begun. The grinding noise that follows indicates catastrophic bearing failure, your turbo's death rattle.

The Silent Killer

More than 90% of turbocharger failures stem from oil-related issues, either contamination or starvation. This statistic reveals the critical relationship between your oil change habits and turbo longevity.

Running a turbocharger without oil for just five seconds causes as much damage as running an engine without oil for five minutes. The microscopic tolerances within the bearing housing depend entirely on a continuous film of clean oil.

Contaminated oil introduces abrasive particles that score bearing surfaces. Metal shavings from worn engine components act like grinding compound, gradually destroying the precision surfaces that allow 300,000 RPM operation. The damage appears slowly, then catastrophically. Drivers notice reduced power, increased oil consumption, or that telltale whistle, all symptoms of internal destruction already underway.

Your oil change interval becomes critical with turbocharged engines. Extended intervals allow oil to break down under extreme heat and pressure. The oil that protects your $30,000 engine becomes the abrasive that destroys your $3,000 turbocharger.

Reading the Early Warning Signs

Smart drivers recognize turbo problems before the whistle begins. Power loss during acceleration indicates restricted airflow or boost leaks. Blue smoke from the exhaust suggests oil seepage past worn seals. Excessive oil consumption points to internal seal deterioration.

The diagnostic process starts with visual inspection. Oil-soaked air intake components indicate turbo seal failure. Shaft play exceeding manufacturer specifications, typically 0.002 to 0.004 inches axially confirms bearing wear requiring immediate attention.

Listen carefully during different operating conditions. Whistling during acceleration suggests boost leaks. Grinding noises at idle indicate bearing damage. Rattling sounds point to loose internal components or foreign object damage.

Modern turbochargers operate in conditions that would destroy conventional components instantly. Understanding these extreme operating parameters helps you appreciate why maintenance matters so critically. Your turbocharger endures exhaust temperatures exceeding 1,000°C while spinning at speeds that blur the line between mechanical engineering and controlled explosion.

The next time you hear that whistle, remember, it's not the sound of performance. It's your turbocharger calling for help before it's too late.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion