One-third of all engine misfires trace back to worn spark plugs, yet most drivers ignore the early warning signs until their morning commute becomes a stuttering nightmare.

Your engine's spark plugs fire 500 times per minute at highway speeds, creating the precise explosions that power your vehicle through millions of combustion cycles. "My car starts fine, so the plugs must be okay," drivers tell themselves while their engine hesitates through every acceleration, burning extra fuel and building carbon deposits that accelerate the damage.

The Hidden Language of Engine Hesitation

That momentary stumble when you press the accelerator speaks volumes about your spark plug condition. Engine hesitation during acceleration represents the most common symptom of failing spark plugs, occurring when worn electrodes can no longer create a strong enough spark to ignite the air-fuel mixture completely.

The physics behind this phenomenon reveal why timing matters so critically. Each spark plug must fire at the precise moment when the piston reaches optimal compression. Worn electrodes with excessive gap require more voltage to jump the distance, causing delayed or weak ignition. The result manifests as that familiar hesitation, your engine literally struggling to complete combustion in one or more cylinders.

Professional technicians recognize this pattern immediately. The hesitation typically appears first under load conditions, accelerating from a stop, climbing hills, or merging onto highways. During these demanding situations, your engine requires maximum power output, exposing the weakness of compromised spark plugs that might perform adequately at idle.

Reading the Electrode Story

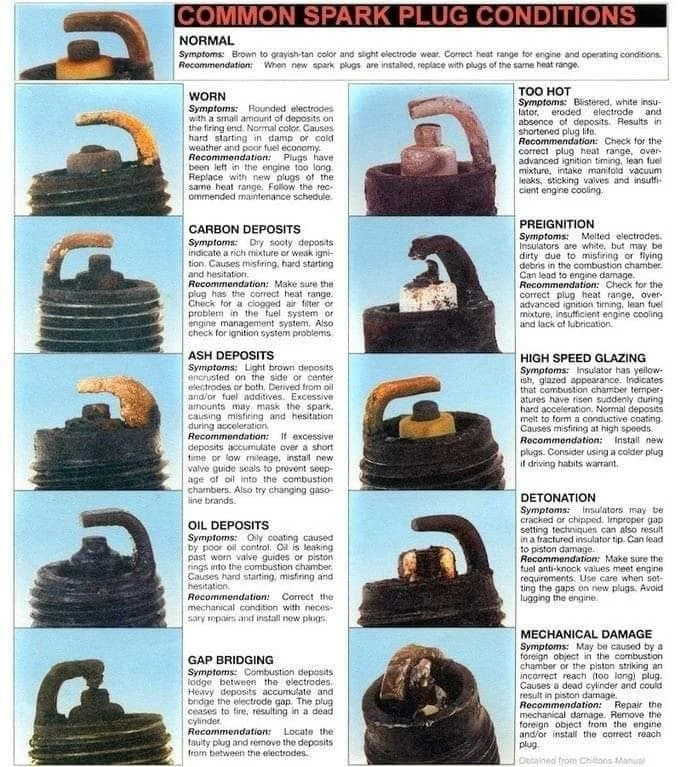

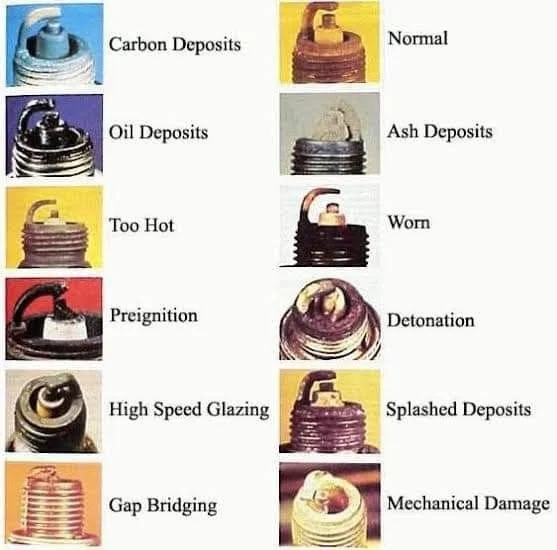

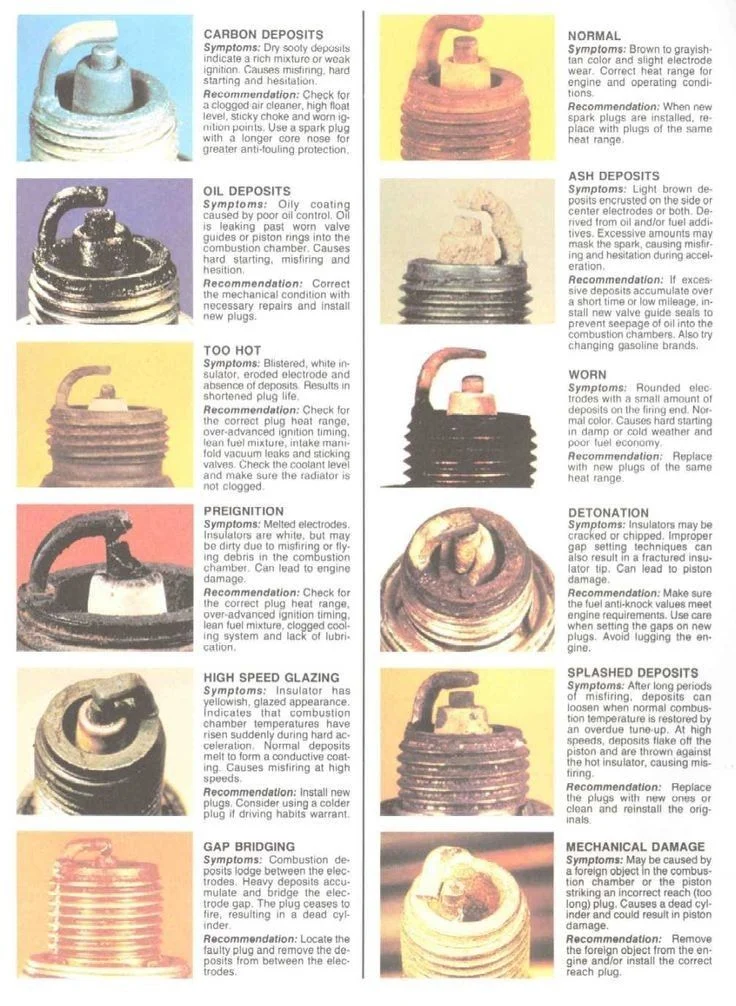

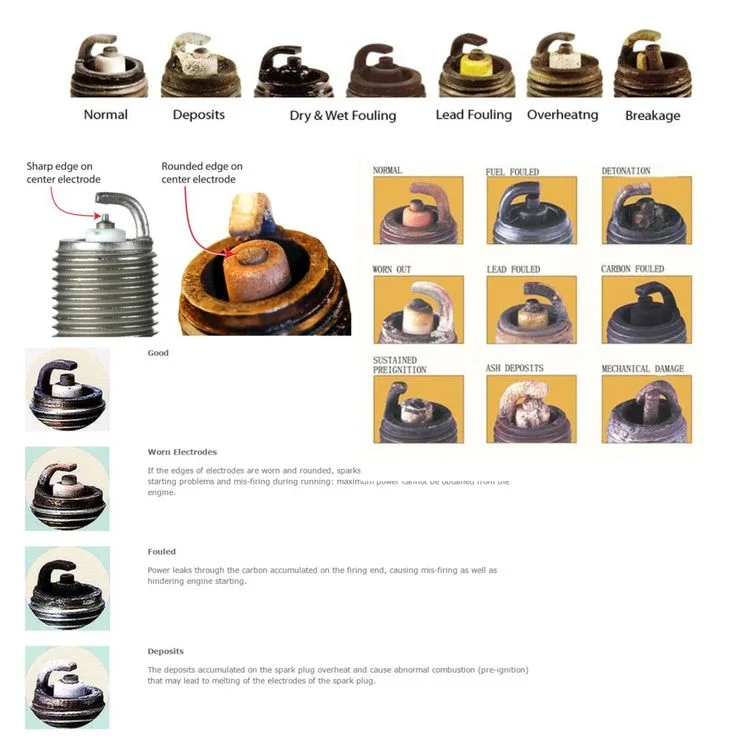

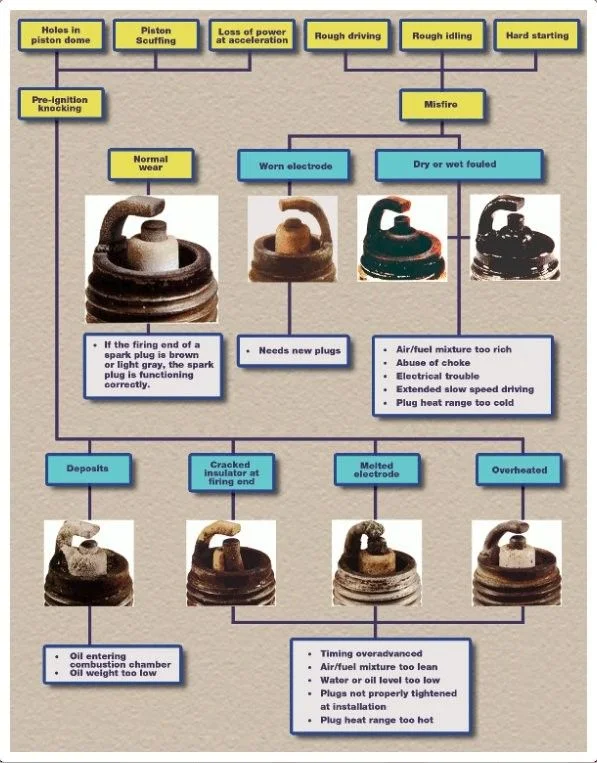

Your spark plugs tell detailed stories about engine condition through their electrode wear patterns. Normal electrode wear creates rounded edges and gradually increases the gap between center and ground electrodes. This natural erosion occurs as thousands of electrical arcs slowly consume the metal surfaces.

When gap measurements exceed manufacturer specifications, typically between 0.028 and 0.060 inches depending on your engine - ignition system performance deteriorates rapidly. The wider gap demands higher voltage from your ignition coil, stressing components throughout the system. Eventually, the coil cannot generate sufficient voltage to reliably jump the excessive gap, resulting in misfires.

Carbon accumulation presents a different diagnostic picture. Black, sooty deposits coating the electrodes indicate rich fuel mixture, weak ignition, or excessive idling. These deposits create alternative electrical paths, allowing spark energy to dissipate without igniting the air-fuel mixture. The engine responds with rough idle, hesitation, and poor fuel economy.

Oil fouling appears as wet, oily deposits covering electrode surfaces. This condition typically indicates worn piston rings, damaged valve seals, or excessive crankcase pressure. Oil-fouled plugs produce weak sparks and frequent misfires, particularly noticeable during acceleration when cylinder pressures peak.

The Cascade of Performance Problems

“It runs fine once it warms up” this common observation reveals how spark plug deterioration affects different operating conditions. Cold starts demand the strongest sparks because fuel vaporization remains incomplete at low temperatures. Worn spark plugs struggle most during these critical moments, causing extended cranking, rough idle, and poor drivability until engine temperatures stabilize.

The progressive nature of spark plug failure often masks symptoms until problems become severe. Initial signs include slightly harder starting and occasional hesitation. As electrode wear continues, symptoms intensify, more frequent misfires, increased fuel consumption, and eventually, complete cylinder dropout during acceleration.

Modern engines with tighter emissions controls amplify these effects. Incomplete combustion from failing spark plugs increases hydrocarbon emissions, potentially triggering catalytic converter overheating. The cascade continues as the damaged catalyst creates backpressure, further reducing engine performance and accelerating spark plug deterioration.

Professional Diagnostic Approach

Professional technicians follow systematic diagnostic procedures when addressing hesitation complaints. The process begins with OBD-II scan tool analysis to identify specific misfiring cylinders. Codes P0300 through P0312 pinpoint random or cylinder-specific misfires, providing the roadmap for targeted diagnosis.

Visual spark plug inspection reveals critical information about engine condition. Technicians examine electrode wear, carbon deposits, oil contamination, and gap measurements. Each spark plug tells part of the engine's operational story, cylinder specific problems become apparent through comparative analysis.

The swap test provides definitive confirmation when symptoms point toward ignition system failure. Moving suspected components between cylinders determines whether problems follow the part or remain cylinder-specific. If hesitation moves with the swapped spark plug, replacement becomes the logical solution.

Advanced diagnostic equipment measures ignition system performance under load conditions. Oscilloscopes reveal spark duration, intensity, and consistency across all cylinders. This technology identifies marginal components before complete failure occurs, preventing the cascade of problems that develop when drivers ignore early warning signs.

Prevention Through Understanding

Smart maintenance prevents the majority of spark plug-related hesitation problems. Understanding replacement intervals helps avoid premature failures, conventional copper plugs typically require replacement every 30,000 miles, while platinum and iridium varieties last 60,000 to 100,000 miles under normal conditions.

Operating conditions significantly impact spark plug longevity. Frequent short trips, excessive idling, and stop-and-go traffic accelerate electrode wear and carbon accumulation. High-performance applications demand more frequent inspections due to increased combustion pressures and temperatures.

Quality matters when selecting replacement spark plugs. OEM-specified heat ranges ensure optimal performance across all operating conditions. Installing plugs with incorrect heat ranges creates problems, too hot causes pre-ignition and electrode melting, while too cold allows carbon fouling and weak combustion.

The next time your car hesitates during acceleration, remember that your spark plugs are trying to communicate. Listen to their message before that small hesitation becomes a major repair bill.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion