Here's a statistic that might surprise you: Fuel delivery failures contribute to 6% of sudden vehicle stalls according to NHTSA crash reports.

That's roughly 1 in every 17 unexpected breakdowns you see on the highway. Yet most drivers never think about their fuel pump until it's too late.

I've been working on fuel systems for over two decades, and I can tell you this much. The worst place to discover a failing fuel pump isn't in your driveway on a Saturday morning. It's doing 70 mph in the left lane when traffic is heavy and your exit is still five miles away.

The Silent Killer Under Your Gas Tank

Your fuel pump doesn't announce its impending death with a dramatic bang or obvious smoke signals. It whispers its warnings through subtle symptoms that most drivers dismiss as "quirks" their car has developed. The scary part? A weak fuel pump can operate normally for months before catastrophically failing without a moment's notice.

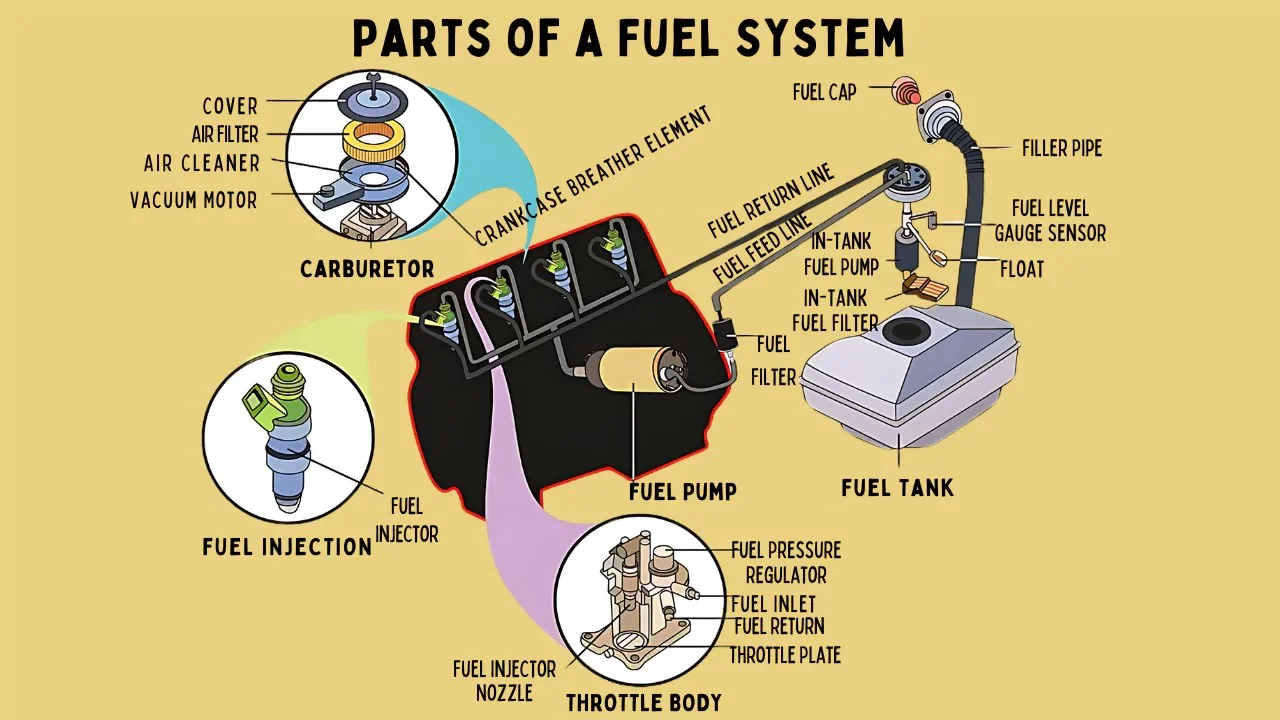

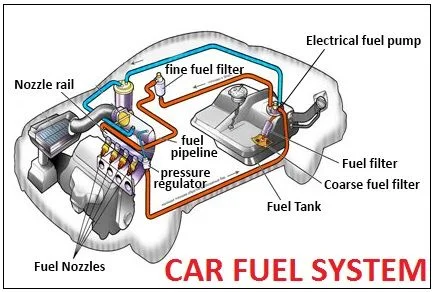

Here's what actually happens inside your fuel system when the pump starts weakening. The electric motor that drives your fuel pump gradually loses efficiency. Instead of maintaining the steady 30-50 PSI pressure your engine needs (depending on your vehicle), it starts struggling to keep up with demand. Think of it like a heart that's slowly losing its ability to pump blood effectively.

During city driving at lower RPMs, your weakened pump might still deliver adequate fuel. Your engine runs fine, maybe with occasional hesitation that you attribute to "needing better gas." But step on the highway where your engine demands maximum fuel flow, and that marginal pump hits its breaking point.

Why Highway Driving Exposes Weak Pumps

Highway speeds create the perfect storm for fuel pump failure. Your engine operates at sustained high RPM, demanding consistent fuel delivery that a weakening pump simply cannot provide. The pump motor runs hotter due to increased workload. Heat accelerates wear on internal components. Eventually, something gives.

I've seen this scenario countless times. A customer calls from the shoulder of I-95, frustrated and confused. "The car was running perfectly fine this morning," they say. "I know my vehicle!" But what they didn't realize was that their fuel pump had been sending distress signals for weeks.

The pressure drop happens gradually, then suddenly. Your fuel pump might deliver 45 PSI when your engine needs 48 PSI. That small deficit won't cause immediate stalling, but it reduces power and efficiency. Then one day, internal pump components finally wear beyond their limits, pressure drops to 20 PSI, and your engine shuts down instantly.

Early Warning Signs You Cannot Ignore

Professional diagnosis starts with recognizing the subtle symptoms that precede complete fuel pump failure. Here are the specific signs I tell every customer to watch for:

- Extended cranking before startup - If your engine takes longer to start than usual, especially after sitting overnight, your fuel pump is likely losing its ability to maintain residual pressure in the fuel lines.

- Engine sputtering at highway speeds - This is the most critical early warning sign. When your engine stumbles or hesitates during highway acceleration, your fuel pump cannot keep up with demand. This symptom often appears months before complete failure.

- Sudden power loss during acceleration - If your car feels like it's "running out of breath" when you press the accelerator, particularly when merging onto highways, insufficient fuel delivery is the likely culprit.

- High-pitched whining from the fuel tank area - A healthy fuel pump operates almost silently. Audible whining indicates internal wear and impending failure.

Testing Your Fuel Pump Before It Fails

Don't wait for roadside drama to check your fuel pump health. Professional testing requires a fuel pressure gauge connected to your vehicle's test port, typically located on the fuel rail. Most modern gasoline engines should maintain 30-50 PSI at idle, though specifications vary by manufacturer.

Here's the testing procedure I use in my shop:

- Connect the pressure gauge to the fuel rail test port using the appropriate adapter. Turn the ignition to "on" without starting the engine. The pump should immediately build pressure to specification. Start the engine and observe pressure at idle. Rev the engine to 2,500 RPM and watch for pressure drops.

- Critical measurement: pressure retention. Turn off the engine and monitor how quickly pressure bleeds down. A healthy system should maintain pressure for at least 10 minutes. If pressure drops rapidly, either the pump check valve is failing or you have internal fuel system leaks.

For vehicles without accessible test ports, fuel pump current draw testing provides valuable diagnostic information. A pump drawing excessive amperage indicates internal wear and impending failure.

The Real Cost of Ignoring the Warning Signs

Beyond the obvious safety risks of highway stalling, weak fuel pumps create cascading problems throughout your fuel system. Inconsistent fuel pressure forces your engine to run lean under certain conditions, potentially damaging expensive components like catalytic converters and oxygen sensors.

Here's something most drivers don't consider: A failing fuel pump rarely fails completely on the first attempt. It typically experiences intermittent failures that become progressively more frequent. Each failure episode subjects your engine to fuel starvation, which can cause misfiring and internal engine damage.

I've seen customers spend thousands on unnecessary engine repairs because they ignored early fuel pump symptoms. The engine damage occurred not from the pump failure itself, but from months of inadequate fuel delivery that preceded the final breakdown.

Failure Prevention Strategies

Fuel pump longevity depends heavily on how you treat your fuel system. Never run your tank below one-quarter full. The fuel pump relies on gasoline for cooling and lubrication. Operating with low fuel levels forces the pump to work harder and run hotter, accelerating wear.

Use quality fuel from reputable stations. Contaminated fuel with water or debris damages pump internals and shortens operational life. The few cents you save buying cheap gas cost dollars in premature pump replacement.

Replace your fuel filter according to manufacturer intervals. A clogged filter forces your pump to work against increased back-pressure, leading to premature failure. Most vehicles require filter replacement every 30,000-50,000 miles, though some newer vehicles have lifetime filters integrated into the pump assembly.

When Professional Intervention Becomes Critical

If you're experiencing any combination of the warning signs I've described, professional diagnosis is essential. Fuel pump replacement typically costs between $400-800 for most vehicles, depending on pump location and labor requirements. That's significantly less than the potential costs of engine damage from fuel starvation or the safety risks of highway stalling.

Don't attempt DIY fuel pump replacement unless you have proper equipment and experience. Fuel systems operate under pressure and contain volatile liquids. Improper procedures can result in dangerous fuel leaks or fires.

The bottom line is this: your fuel pump gives you warnings before it fails completely. Learning to recognize and respond to these signals can save you from dangerous highway stalls, expensive engine damage, and the frustration of unexpected breakdowns. Trust the symptoms your vehicle is showing you, and address fuel system problems before they leave you stranded.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion