A faulty oxygen sensor can silently rob you of up to 15% of your fuel economy. That's roughly 3 - 4 miles per gallon vanishing from your tank without any obvious warning signs.

For the average American driver covering 15,000 miles annually, this translates to an extra $300-400 spent at the pump each year.

Hidden beneath your hood lies one of the most crucial yet overlooked components in your vehicle's fuel management system. While drivers obsess over tire pressure and oil changes, oxygen sensors quietly orchestrate a complex dance of combustion efficiency that directly impacts every gallon you pump.

What Oxygen Sensors Actually Do Behind The Scenes

Your oxygen sensor functions as your engine's financial advisor. It constantly monitors the exhaust gases flowing from your engine and reports back to the computer about fuel consumption efficiency. Think of it as a microscopic accountant that never sleeps, working 24/7 to ensure your engine burns exactly the right amount of fuel.

The sensor measures unburned oxygen in your exhaust stream. When oxygen levels are high, it signals your engine is running lean and needs more fuel. When oxygen levels are low, it indicates a rich mixture that's wasting precious gasoline.

The ideal air-to-fuel ratio sits at exactly 14.7 parts air to 1 part fuel. This precise balance represents the sweet spot where combustion efficiency peaks and fuel waste minimizes. Your oxygen sensor helps maintain this ratio through continuous feedback loops occurring multiple times per second.

Modern vehicles typically house at least two oxygen sensors. The upstream sensor sits before your catalytic converter and directly controls fuel mixture. The downstream sensor monitors catalytic converter efficiency. Larger V6 and V8 engines may contain four sensors working in harmony.

The Hidden Fuel Economy Killer

Many drivers remain completely unaware their oxygen sensors are failing. "My car runs fine," they'll say, while unknowingly burning through extra gallons each week. The degradation happens gradually, making it nearly impossible to notice day-to-day changes in fuel consumption.

When oxygen sensors deteriorate, your engine defaults to a rich fuel mixture as a protective measure. This safety protocol prevents engine damage but sacrifices fuel economy in the process. Research indicates this default mode can increase fuel consumption by 10-20% compared to optimal performance.

The financial impact compounds quickly. Consider a vehicle averaging 25 miles per gallon experiencing a 15% efficiency loss. That drops fuel economy to approximately 21.25 miles per gallon. Over 15,000 annual miles, this represents an additional 118 gallons of fuel consumed, or roughly $413 in extra costs at current fuel prices.

Temperature extremes and altitude changes place additional stress on oxygen sensors. High-altitude locations like Albuquerque (elevation 5,300 feet) demand harder work from sensors due to thinner air containing less oxygen. This increased workload can accelerate sensor degradation, particularly in older vehicles.

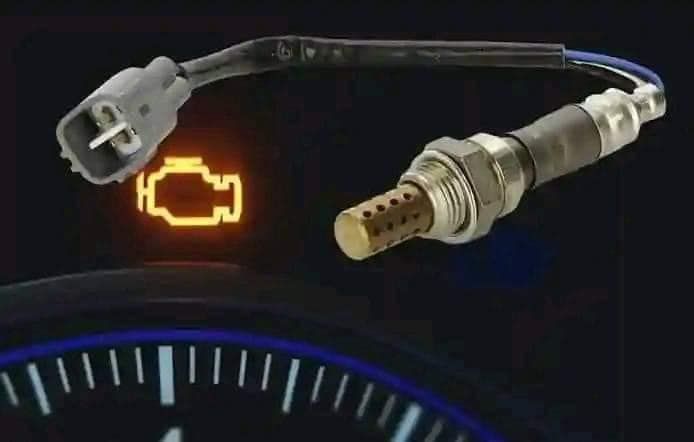

Recognizing The Warning Signs

The check engine light represents the most obvious indicator of oxygen sensor problems. However, many drivers dismiss this warning, adopting the "it'll fix itself" mentality. Professional diagnostic scanning reveals specific trouble codes ranging from P0130 to P0167, all indicating oxygen sensor circuit malfunctions.

Decreased fuel economy often serves as the first real-world symptom drivers notice. You might find yourself filling up more frequently or traveling fewer miles per tank. This decline typically occurs gradually, making it easy to attribute to other factors like traffic patterns or seasonal fuel blends.

Poor engine performance manifests through hesitation during acceleration, rough idling, or general sluggishness. "It doesn't have the same pep anymore," drivers often report, not realizing their fuel system is compromised. The engine struggles to maintain optimal performance when deprived of accurate air-fuel mixture data.

A failed emissions test frequently serves as the wake-up call many drivers need. States with mandatory emissions testing catch oxygen sensor problems that might otherwise go undetected for months or years. The sensor's role in controlling pollutant output makes it a critical component for environmental compliance.

Rough idle or stalling at stops indicates severe sensor deterioration. The precise balance needed for smooth operation at idle becomes impossible when sensors can't accurately measure exhaust gas composition. Some drivers experience intermittent stalling that seems to come and go randomly.

A distinct rotten egg smell from the exhaust suggests the problem has progressed beyond simple sensor failure. This sulfur odor indicates your catalytic converter is working improperly due to incorrect oxygen sensor input, potentially leading to much more expensive repairs.

The True Cost Of Ignoring Sensor Problems

Delaying oxygen sensor replacement creates a domino effect of expensive problems throughout your vehicle's systems. The most immediate risk involves catalytic converter damage, where unburned fuel can ignite inside the converter, creating temperatures that melt internal components. Catalytic converter replacement typically costs $1,500 to $3,000, making oxygen sensor maintenance look like a bargain.

Spark plugs suffer when engines run rich consistently. Carbon buildup on electrodes leads to misfires and fouled plugs, creating rough running conditions and poor acceleration. "The engine shakes like it's angry," one driver described their experience with fouled spark plugs caused by sensor failure.

Fuel injectors must work harder when responding to faulty sensor signals, potentially shortening their operational life. The increased workload on injectors can lead to premature failure requiring expensive cleaning or replacement services.

Engine oil contamination accelerates when excess fuel washes down cylinder walls. This dilutes the oil and reduces its lubricating properties, accelerating wear on pistons, cylinder walls, and bearings. While this damage develops slowly, consistent operation with bad sensors reduces overall engine longevity.

Professional Diagnosis And Replacement Economics

Quality oxygen sensor replacement typically costs $200-$500 per sensor including labor. This investment pays for itself through improved fuel economy within 12 to 24 months for most driving patterns. Professional diagnosis ensures the correct sensor gets replaced and related problems get addressed.

DIY replacement can reduce costs to $40 to $250 for parts alone, but requires specialized oxygen sensor sockets and basic mechanical knowledge. Access varies significantly between vehicle makes and models, with some sensors easily reached while others require extensive disassembly.

Choose OEM or quality aftermarket sensors over generic universal options. Cheap sensors may not provide accurate readings for your specific vehicle, potentially causing continued performance issues or triggering check engine lights. Major brands like Bosch, Denso, and NTK generally offer superior reliability and longevity.

The return on investment calculation strongly favors prompt replacement. A vehicle driven 15,000 miles annually with 25 MPG experiencing 10% efficiency improvement saves approximately $210 per year in fuel costs. Even professional replacement at $350 breaks even within 20 months, not counting performance improvements and prevented damage.

Preventive Maintenance For Maximum Sensor Life

Address exhaust leaks promptly to prevent false oxygen sensor readings. Leaks before the sensor allow outside air to enter the exhaust stream, causing erratic signals that confuse the engine computer. Regular exhaust system inspection catches these problems before they affect sensor performance.

Use quality fuel consistently to minimize contaminant buildup on sensor elements. Low-quality gasoline may contain impurities that coat the sensor's ceramic element, reducing accuracy over time. "You get what you pay for with fuel," experienced mechanics often remind customers.

Maintain proper engine tune-up schedules to produce cleaner exhaust gases. A well-maintained engine with fresh air filters, quality spark plugs, and clean fuel injectors creates optimal conditions for sensor longevity. Regular maintenance prevents the contamination that shortens sensor life.

Fix oil consumption issues immediately when detected. Oil burning in the combustion chamber can coat oxygen sensors with residue that permanently damages their ability to generate accurate readings. Blue smoke from the exhaust indicates oil consumption requiring immediate attention.

Consider periodic use of quality fuel system cleaners to prevent deposit buildup throughout the fuel delivery system. While not a cure-all, these additives can help maintain cleaner combustion and extend sensor service life when used as part of regular maintenance.

The Technology Behind The Efficiency

Modern oxygen sensors represent sophisticated electrochemical devices that generate voltage signals based on oxygen concentration differences. The sensor element typically produces 0.1 volts when detecting lean exhaust conditions and 0.9 volts during rich conditions. The engine computer constantly monitors these voltage fluctuations to maintain the ideal 14.7:1 air-fuel ratio.

Heated oxygen sensors reach operating temperature faster than older unheated designs, improving cold-start emissions and fuel economy. The heating element allows sensors to provide accurate readings within seconds of startup rather than waiting for exhaust heat to warm the sensor element.

Wideband air-fuel ratio sensors found in newer vehicles provide more precise measurements across broader operating ranges. These advanced sensors enable ultra-fine control of emissions in increasingly stringent regulatory environments while maintaining optimal fuel economy across all driving conditions.

Understanding oxygen sensor technology helps drivers appreciate why these components deserve attention in maintenance schedules. The sophistication packed into these small devices enables the fuel efficiency we've come to expect from modern vehicles.

Oxygen sensors may operate quietly behind the scenes, but their impact on your wallet speaks volumes. Regular inspection and timely replacement of these critical components ensures your vehicle delivers the fuel economy you paid for while preventing expensive downstream repairs. Don't let faulty sensors silently drain your fuel budget when a straightforward replacement can restore efficiency and save money for years to come.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion