Your engine's humming along at 70 mph when suddenly, nothing. The power drains like someone pulled the plug, and you're coasting toward the shoulder with your hazards flashing and your heart racing.

Fuel system failures represent a significant portion of highway breakdowns nationwide, and a failing fuel pump sits right at the center of this problem. I've seen this scenario play out hundreds of times in my career, and the terrifying part? Most drivers have no idea it's coming.

The Critical Role Your Fuel Pump Actually Plays

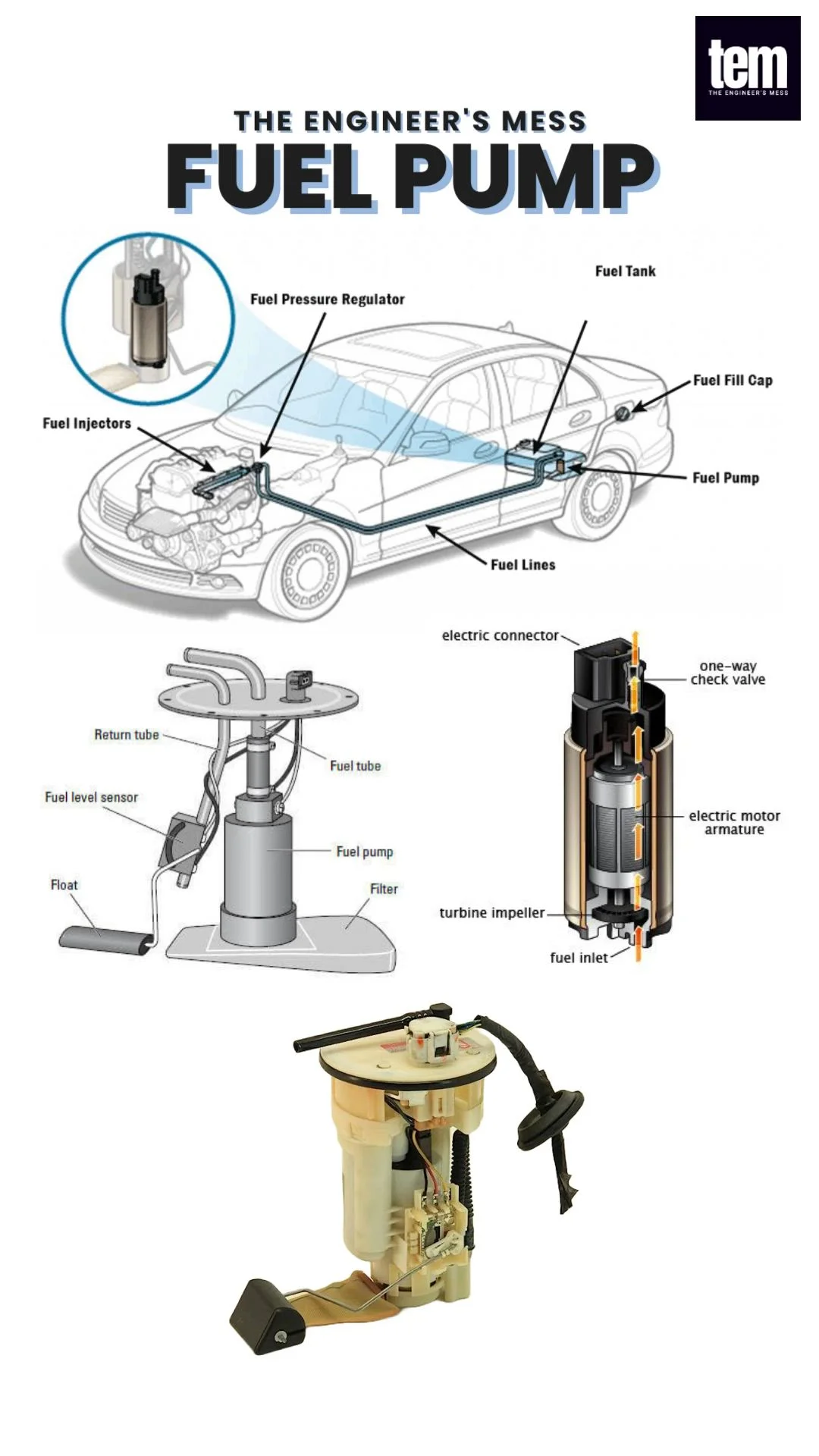

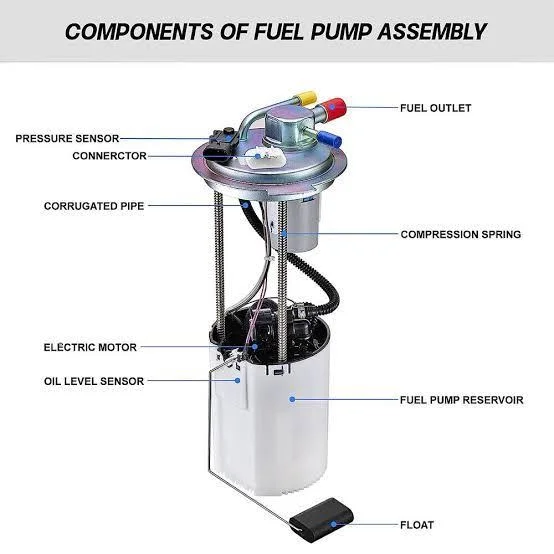

Your fuel pump does exactly what it sounds like, it pumps fuel from your tank to your engine. Simple, right? Wrong. Modern fuel pumps operate under extreme conditions, generating pressures between 45 and 65 PSI in most Electronic Fuel Injection systems, according to research from automotive fuel system manufacturers. Some high-performance and direct injection systems demand even more, exceeding 100 PSI or reaching up to 2,500 bar in modern diesel common rail systems. That's serious force happening thousands of times per minute while submerged in gasoline.

Electric fuel pumps, which replaced mechanical versions in most vehicles after the 1980s, work constantly whenever your engine runs. They spin at thousands of RPM, pushing fuel through lines, filters, and injectors with relentless precision. When these pumps begin to fail, they rarely give you the courtesy of dying completely in your driveway. Instead, they deteriorate gradually, and highway speeds become their breaking point.

Why Highway Speeds Trigger The Failure

Here's where things get technical, and understanding this will save you from being stranded. At idle or city speeds, your engine demands relatively modest fuel flow. We're talking maybe 0.2 to 0.5 gallons per hour when idling, according to Department of Energy research on fuel consumption rates. But when you're cruising at highway speeds? That demand skyrockets. Your engine suddenly needs significantly more fuel volume per minute to maintain power output at 65 or 70 mph.

A failing fuel pump that can barely keep up at lower speeds reaches its absolute limit when you hit the highway. The weakened motor inside the pump struggles to maintain the pressure needed to deliver adequate fuel flow. When pressure drops even slightly below spec, your fuel injectors cannot spray the correct amount of fuel into the combustion chambers. The result? Sudden power loss, engine sputtering, or complete stalling.

Think of it like trying to water your lawn with a hose that has a weak pump. At low flow, you might get by. Turn the tap to maximum, and you'll see the real problem appear immediately. Your engine experiences the same limitation when a compromised fuel pump cannot meet high-speed fuel demands.

Heat Makes Everything Worse

I can't tell you how many times I've heard drivers say, "I'll make it home" when their low fuel light comes on. Here's a reality check: your fuel pump depends on gasoline for cooling and lubrication. When you consistently run your tank below one-quarter full, the pump loses that cooling effect. Arnold Motor Supply explains that electric fuel pumps generate substantial heat during operation, and fuel acts as the primary coolant. Without adequate fuel surrounding the pump motor, temperatures rise dramatically.

Overheating weakens internal components over time. Seals deteriorate. Brushes wear faster in the electric motor. Bearings lose lubrication. This cumulative damage might not show symptoms during short trips around town, but highway driving demands sustained high output from an already-compromised pump. The combination of increased fuel demand and elevated operating temperature creates the perfect storm for failure at the worst possible moment.

According to automotive research, repeatedly driving with less than a quarter tank is one of the most common causes of premature fuel pump failure. The pump can overheat when not fully submerged, leading to burnout long before the typical 100,000 to 150,000-mile lifespan.

The Warning Signs You're Probably Ignoring

Fuel pumps rarely fail without warning, though drivers often miss the early signals. Engine sputtering at highway speeds is the classic red flag. You'll feel it, that momentary hesitation or brief loss of power that makes you wonder if something's wrong. Many drivers dismiss it, thinking "my car always does that." No, it doesn't. That's your fuel pump screaming for attention.

Loss of power when accelerating or climbing hills represents another critical warning sign. When you stomp the accelerator and the engine hesitates or struggles to respond, insufficient fuel delivery is frequently the culprit. A healthy fuel pump should provide instant response to throttle input at any speed.

Unusual whining noises from your fuel tank area serve as another telltale symptom. Fuel pumps make some noise, that's normal. But a high-pitched whine that increases with engine speed or changes character signals bearing wear or motor strain. This noise often appears weeks or months before complete failure, giving you a window to address the problem.

Difficulty starting deserves immediate attention. If your engine cranks longer than usual before firing up, or requires multiple attempts to start, your pump may be struggling to build adequate pressure in the fuel rail. This symptom typically worsens gradually, with start times increasing over weeks until one day the pump gives up entirely.

What You Need To Do Right Now

- First, stop gambling with your fuel level. Keep your tank above one-quarter full at all times. Yes, that means filling up more frequently, and yes, I know fuel is expensive. But a fuel pump replacement costs between $400 and $800 at most shops, and getting stranded on the highway isn't free either. The few dollars you save by running empty aren't worth the risk.

- Second, replace your fuel filter according to your vehicle's maintenance schedule. Many modern cars have lifetime filters integrated into the fuel pump assembly, but if yours has a serviceable filter, replace it every 30,000 to 50,000 miles. A clogged filter forces your pump to work harder, accelerating wear and bringing you closer to failure.

- Third, use quality fuel from reputable stations. Contaminated fuel containing dirt, rust, or water damages fuel pumps rapidly. Those bargain-basement gas stations? They might save you five cents per gallon while introducing contaminants that destroy a $600 component. Not worth it.

Finally, if you're experiencing any of the warning signs I've described, get your vehicle to a qualified technician immediately. A fuel pressure test takes minutes and costs minimal money compared to a roadside breakdown. Technicians measure fuel pressure at the rail and compare it against manufacturer specifications. Readings below spec indicate pump weakness, even if the pump hasn't failed completely yet.

The Bottom Line

Fuel pump failures at highway speeds aren't mysterious or unpredictable. They result from wear, heat, contamination, and increased demand at high speeds overwhelming a compromised component. The good news? You have control over many factors that influence pump longevity. Keep your tank reasonably full, maintain your fuel filter, use quality gasoline, and pay attention to warning signs.

Your fuel pump should last 100,000 miles or more with proper care. Many exceed 150,000 miles or even 200,000 miles. But consistently running low on fuel, ignoring maintenance, or dismissing early warning symptoms will guarantee you experience that terrifying moment of sudden power loss on the highway.

Don't wait until you're coasting onto the shoulder with your hazards flashing. Your fuel pump is telling you what it needs, you've got to listen.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion