Here's something that'll make you wince: nearly 35% of catastrophic engine failures could have been prevented with basic maintenance, according to data from the Automotive Maintenance and Repair Association.

Mike Torres has rebuilt over 100 engines in his 22-year career. Most of them, he says, never needed to land on his workbench. They died young because someone got cocky, cut corners, or believed a YouTube video over physics.

"I thought I could make it home," is what he hears when the tow truck drops off another seized motor. Or his personal favorite: “The internet said this was an easy fix.”

After a hundred teardowns, Torres has seen patterns emerge. The same mistakes. The same expensive consequences. And he's agreed to share what separates a $200 repair from a $4,000 engine replacement.

The Jobs You Should Never Touch Yourself

"Timing belt replacement tops my list. Period," Torres says, leaning against a disassembled Honda Accord in his shop.

He's seen shade-tree mechanics install timing belts backward. The engine ran for exactly 11 seconds before the valves kissed the pistons at high speed.

“Here's what happens: you're off by one tooth on the cam gear. Just one. The engine starts, runs rough, and within 200 miles, you've got bent valves. Now you're looking at a cylinder head rebuild on top of the timing belt you already paid for.”

Head gasket replacement falls into the same category. It requires precision torque sequences, perfectly clean mating surfaces, and the knowledge to spot a warped head before you bolt everything back together.

"'I'll just crank down these bolts real good' has created more comebacks than I can count," he laughs.

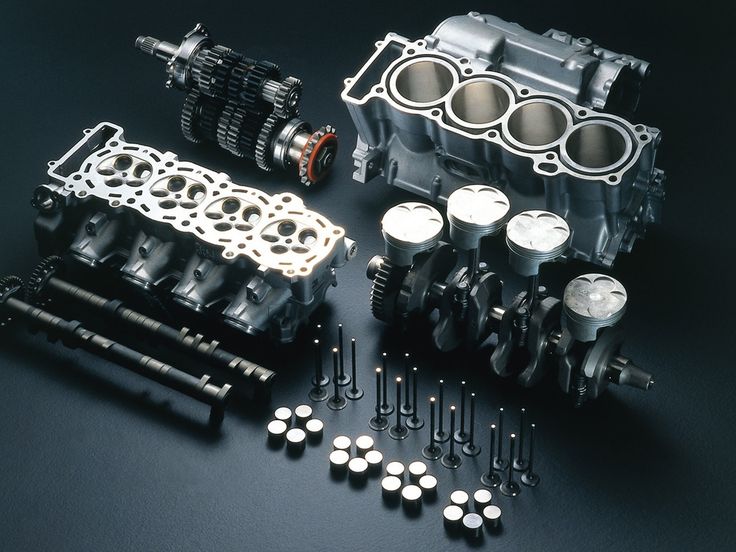

And engine bearing replacement? Forget it. Torres shows me a micrometer and plastigage, tools that measure tolerances in thousandths of an inch. One customer tried this at home, got the rod caps mixed up, and destroyed a $2,800 crankshaft in under five minutes of run time.

Those "Cheap Fixes" That'll Cost You Everything

Torres pulls a bottle of stop-leak from his shelf like it's contaminated.

"My mechanic wanted $600 to fix the head gasket, but I found this bottle for $15!" he mimics. “That bottle is going to plug your heater core, gum up your thermostat, and potentially clog the narrow passages in your oil cooler.”

He shows me photos of an engine he pulled last month. So much stop-leak sludge inside, it looked like someone poured concrete through the cooling system. The original leak? A $40 hose connection.

Universal oxygen sensors are another trap, according to Torres. Yes, they're $60 instead of $240. They're also wrong 40% of the time because they don't match your ECU's voltage curve exactly.

“Your check engine light might go off, but your fuel trims will be incorrect, you'll lose fuel economy, and you might damage your catalytic converter. That $180 savings becomes a $1,400 repair.”

Then there's mixing oil weights. "It's all oil, right?" people say. Wrong.

“Your engine was engineered for specific viscosity ranges. That 20W-50 racing oil might seem like extra protection, but in a modern engine designed for 0W-20, it'll starve your variable valve timing system and score your cam journals.”

And the small leaks people ignore? “It's dripping on your serpentine belt, which will slip and fail to drive your water pump, which will overheat your engine, which will warp your head. Fifteen bucks of oil turned into $3,200 real fast.”

How to Catch a Worn Rod Bearing Before It's Too Late

Torres gets animated about this one. “This saves engines!”

Cold start knock. If you hear a distinct rapping noise for the first 3-5 seconds after starting a cold engine, and it goes away once oil pressure builds, you've got bearing wear starting.

"It's not lifter noise," he insists. “It's not normal. It's your connecting rod bearings telling you they've lost their crush tolerance and the clearances have opened up.”

He demonstrates the sound, a deep, heavy thump that matches engine RPM exactly. Normal valve train noise is a light ticking, almost like a sewing machine. Rod knock is deeper.

“Oil analysis will confirm it. For $35, Blackstone Labs will tell you exactly how many parts per million of copper and lead are in your oil. Copper comes from bearings. When your copper count jumps from 15 ppm to 80 ppm between oil changes, you know something's eating itself inside.”

The catch? You've got maybe 5,000 miles once that knock starts. Address it now with new bearings, a $1,200 job. Ignore it? Full engine rebuild at $4,500 minimum.

"'I'll just keep adding oil and drive it until it dies,' one customer told me," Torres recalls. “It died on the highway. The rod exited through the block.”

The One Thing That'll Actually Prevent Oil Sludge

"Change your oil on time with quality products!" Torres practically shouts. “Not rocket science, right?”

Yet half the sludged engines he tears down have 15,000-mile oil change intervals because “the manufacturer says it's fine.”

“Manufacturers design service intervals around warranty periods and marketing. They want to advertise low cost of ownership with 10,000-mile oil changes. What they don't advertise is that in severe service conditions of stop-and-go traffic, short trips under 10 miles, extreme temperatures that interval should be cut in half.”

Modern direct injection systems introduce gasoline into your oil through blow-by, Torres explains. Five thousand miles of city driving and your oil has thinned and contains fuel contamination. By 10,000 miles, you're cooking that oil into varnish.

His recommendation: full synthetic, every 5,000 miles regardless of what your maintenance minder says, with a quality filter. Not the $3.99 special but the $12 Wix or Mobil 1 filter.

"I opened a Nissan V6 last year with perfect maintenance records. Full synthetic every 5,000 miles. The inside looked factory-fresh at 160,000 miles." The owner's secret? Gentle driving for the first few miles of every trip until the oil warmed up.

How to Actually Choose a Reputable Shop

Torres has strong opinions here. Forget Yelp reviews.

“Half are fake, and the other half are written by people who think they 'know their vehicle' before they even arrive.”

His method: walk into the shop unannounced. Look at the parking lot. Are there newer vehicles mixed with older ones? Good sign. Are the bays organized or chaotic?

“Ask to see their scanner. A quality shop will have a bi-directional scan tool, not a $50 code reader. Bi-directional means they can command systems on and off, watch live data streams. That equipment costs $5,000+ annually. If they're investing in tools, they're investing in accuracy.”

Ask about their diagnostic process. If they immediately quote you a repair without diagnosis……. red flag.

“'Your check engine light is on, so you need an oxygen sensor' is lazy. Maybe you do. Or maybe you have a vacuum leak, an exhaust leak, or a failed MAF sensor throwing the readings off.”

And the big one: ask what warranty they offer on their work. “A confident shop warranties labor and parts for at least 12 months or 12,000 miles. Shops that won't stand behind their work shouldn't be touching your car.”

The One Trick That'll Genuinely Save Your Engine

Torres leans forward. “You want the secret? Check your oil every single time you fill up with gas.”

Simple. Boring. Effective.

"I cannot tell you how many engines I've rebuilt that died because someone ignored the oil light until it was too late." Engines consume oil. All of them. Some burn an ounce every thousand miles, some burn a quart every five hundred.

Pop the hood, pull the dipstick, wipe it clean, reinsert it fully, pull it again, and check the level. Takes 45 seconds.

“This habit has saved more engines than any additive, any oil brand, any magic product ever could. Because you catch the small problems early.”

"'My car tells me when it's low,' they say, pointing at the oil life monitor," Torres shakes his head. “That monitor tracks miles and driving conditions. It does NOT measure actual oil level in most vehicles. By the time your oil pressure warning light comes on, you're already damaging bearings.”

That light illuminates at around 5-7 psi. Your engine needs 10 psi per 1,000 RPM to survive. At idle, you might be okay. On the highway? You're welding your bearings to your crank.

After talking with Torres for two hours, one thing becomes clear: engines don't fail randomly. They fail because we fail them. We skip maintenance, ignore warning signs, or attempt repairs beyond our skill level.

"Your engine will communicate with you if you listen," he says, wiping his hands on a shop towel. “That slight knock, that increased oil consumption, that rougher-than-normal idle—they're all warning signs.”

His final advice? Check your oil. Use quality parts. Find a shop that earns your trust through transparency. And maybe don't trust that video titled "EASY Engine Rebuild in Your Driveway!!!" with 47 views.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion