One in three drivers will experience a vehicle breakdown annually, and here's the kicker: 30% of those roadside emergencies stem from battery failures, while alternator problems rank as the second most common electrical issue.

Yet ask most drivers which component actually keeps their car running, and you'll get confused stares or confident wrong answers.

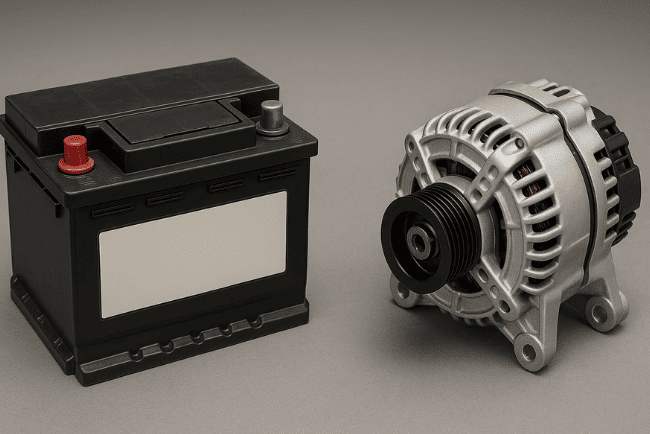

I've been diagnosing electrical failures for over fifteen years, and I can tell you this much. The relationship between your alternator and battery isn't a simple "one powers the other" arrangement. It's a complex partnership where understanding who does what can mean the difference between getting home safely and calling for a tow truck.

The Truth About Who Powers What

Here's what actually happens when you turn that key. Your battery provides the initial burst of power needed to crank your engine and fire up your ignition system. Think of it as the starter pistol in a relay race. Once your engine reaches sufficient RPM, your alternator takes over as the primary power source, supplying electricity to run everything from your headlights to your fuel injection system.

The alternator becomes your car's lifeline once you're moving. Most modern alternators generate 80-100 amperes at full output, easily handling your vehicle's electrical demands while simultaneously recharging your battery. Your typical car battery, meanwhile, stores about 48 amp-hours of power but functions more like a buffer than a primary power source during normal driving.

This is where most people get confused. "My battery is new, so I should be fine!" they say, not realizing that a failing alternator will drain even the best battery within hours of driving.

How Long Each Component Can Keep You Moving

When your alternator fails while driving, you're operating on borrowed time. Your fully charged battery might keep your engine running for 30 minutes to 2 hours, depending on your electrical load and battery condition. Turn on your headlights, air conditioning, and radio, and that time drops dramatically.

I've seen drivers make it 50-100 miles on battery power alone under ideal conditions during daylight hours with minimal electrical usage. However, modern vehicles with fuel injection, electronic ignition, and computer-controlled systems typically consume 20-40 amperes continuously while running. Do the math: a 48 amp-hour battery divided by 30 amperes of consumption gives you roughly 90 minutes of driving time.

When your battery fails, the scenario changes completely. A healthy alternator can actually run your car indefinitely without a battery, though I strongly advise against this practice. Your alternator generates AC power that gets converted to DC through diodes, but without a battery to smooth out voltage fluctuations, you risk damaging sensitive electronic components.

The Real Cause Behind Most Electrical Failures

Battery failures dominate breakdown statistics for good reason. Car batteries typically last 3-5 years, with replacement cycles becoming necessary due to internal plate deterioration and electrolyte breakdown. Heat accelerates this process significantly, which explains why vehicles in warmer climates see shorter battery life.

Alternators, however, often outlast multiple batteries when properly maintained. The typical alternator failure results from worn brushes, faulty diodes, or bearing problems. These components can last 100,000-150,000 miles under normal conditions, making alternator replacement less frequent but more expensive when it occurs.

Here's something most mechanics won't tell you upfront: alternator problems often masquerade as battery issues. A failing alternator undercharges your battery, causing premature battery failure. Customers replace the battery, drive for a few weeks, then return with the same starting problems because the root cause was never addressed.

Diagnostic Strategies That Actually Work

Professional diagnosis starts with understanding the symptoms each component produces. A battery problem typically manifests as slow cranking or complete failure to start, especially after the vehicle sits overnight. The engine either turns over sluggishly or you hear clicking sounds from the starter solenoid.

Alternator failures present differently. Your engine starts normally but you notice dimming headlights when idling, dashboard warning lights, or electrical accessories behaving erratically. The battery warning light specifically indicates charging system problems, not necessarily battery failure.

- Here's my go-to testing sequence: First, check battery voltage with the engine off. A healthy battery should read 12.6 volts or higher. Start the engine and measure voltage again. You should see 13.5-14.5 volts with the alternator charging properly. If voltage remains below 13 volts with the engine running, your alternator isn't generating sufficient power.

Load testing reveals the complete picture. Apply electrical load by turning on headlights, air conditioning, and other accessories while monitoring system voltage. A healthy alternator maintains proper voltage under load, while a failing unit shows significant voltage drops.

Prevention Tactics That Save Money

Battery maintenance extends lifespan significantly. Keep terminals clean and tight, as corrosion creates resistance that forces both components to work harder. Check electrolyte levels in serviceable batteries monthly, adding distilled water as needed.

Never run your fuel tank below one-quarter full. Your fuel pump relies on gasoline for cooling, and low fuel levels force the pump to work harder, drawing more current from your electrical system. This additional load stresses both your alternator and battery unnecessarily.

Here's something most drivers overlook: short trip driving kills batteries faster than highway miles. Your alternator needs sustained RPM to fully recharge your battery after starting. Multiple short trips prevent complete recharging cycles, gradually depleting battery capacity over time.

Replace your serpentine belt according to manufacturer intervals. A slipping belt reduces alternator output even if the alternator itself remains healthy. I've diagnosed numerous "alternator failures" that were actually worn belt problems costing $30 to fix instead of $500 for alternator replacement.

When Professional Help Becomes Essential

Electrical system problems require proper diagnostic equipment for accurate diagnosis. Battery testers measure not only voltage but also cold cranking amps and internal resistance. Alternator testing requires specialized equipment to evaluate diode function and output regulation under varying loads.

Don't guess which component needs replacement. I've seen too many customers replace batteries when alternators were failing, or vice versa. Professional diagnosis costs significantly less than replacing the wrong component, especially when you factor in the inconvenience of repeated failures.

- The bottom line is this: both components are essential, but they serve different primary functions. Your battery gets you started and provides backup power during electrical demands that exceed alternator output. Your alternator keeps everything running and maintains battery charge during normal operation. Understanding this relationship helps you recognize symptoms early and avoid costly roadside emergencies.

Comments (0)

Please login to join the discussion

Be the first to comment on this article!

Share your thoughts and start the discussion